MIC 12-1 Energy Drink Production Line (1000-2000CPH)

MIC 12-1 Energy Drink Production Line: The Ultimate Solution for High-Efficiency Energy Drink Bottling

Company Introduction

Jiangsu Mic Machinery is a leading innovator in the design and manufacturing of advanced bottling and packaging solutions for the beverage industry. With a commitment to quality, efficiency, and customer satisfaction, our company has become a trusted partner for beverage manufacturers around the world. Our wide range of machinery, including energy drink production lines, soft drink production lines, and various types of drink production lines, are tailored to meet the needs of diverse industries, ensuring precision and reliability at every stage of production.

|

|

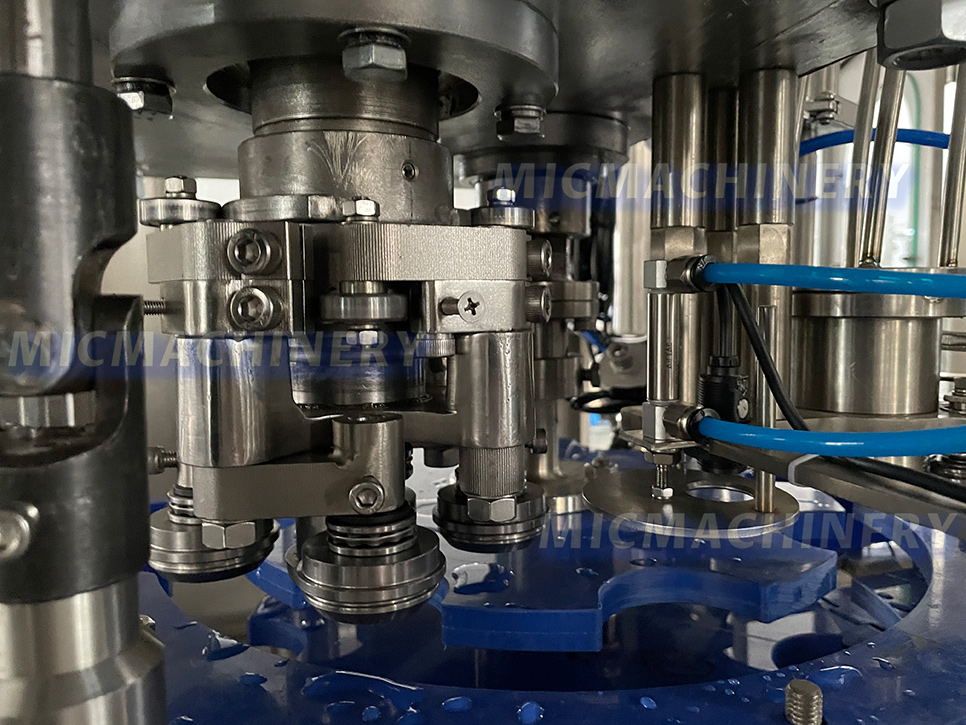

Aluminum can sealing system The aluminum can sealing system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle

The MIC 12-1 energy drink production line operates with cutting-edge automation to efficiently manage the bottling of energy drinks, soft drinks, and other beverages. The process begins with the washing section, where bottles are thoroughly cleaned and sterilized to ensure product safety. Once cleaned, the bottles are moved to the filling station, where precise measurements of energy drink or other beverage products are dispensed. This filling station is designed with advanced technology to maintain the quality and consistency of every bottle, even under high-speed production conditions. After filling, the bottles are securely capped to ensure freshness and prevent contamination. The final stage involves the application of labels, which are affixed with high precision. Throughout the entire process, the system is controlled by an intuitive user interface, allowing for real-time monitoring and adjustments to optimize production flow and maintain high standards of quality.

Function

The MIC 12-1 energy drink production line is built to provide high-speed, high-quality bottling for energy drinks and other carbonated or non-carbonated beverages. Key functions include:

· Bottle Washing: Automated washing and sterilization to ensure cleanliness and product safety.

· Filling: Precise filling technology ensures accurate beverage volumes and preserves the drink's quality and carbonation levels.

· Capping: Secure capping of bottles to prevent leaks and maintain freshness.

· Labeling: High-accuracy labeling for consistent and professional presentation of the final product.

· Automation: Fully automated process for reduced labor costs, faster production speeds, and improved efficiency.

· Versatility: Suitable for a wide range of drinks, including soft drink production lines, carbonated beverages, and more.

Advantages

The MIC 12-1 energy drink production line offers numerous advantages, making it an excellent investment for beverage manufacturers looking to scale up their production while maintaining top-quality standards:

1.High-Speed Production

The system is designed to handle high-speed production, ensuring that large volumes of energy drinks can be bottled efficiently without compromising on quality.

2.Flexible Beverage Handling

Whether you are bottling energy drinks, soft drink production lines, or other beverages, this system can be easily adapted to meet the requirements of different types of drinks, offering flexibility in your production line.

3.Precise and Consistent Filling:

The advanced filling technology ensures that each bottle is filled accurately, maintaining uniformity and reducing product waste.

4.Cost-Effective Operation

Designed for low maintenance and energy efficiency, the MIC 12-1 line reduces operating costs, making it an excellent choice for businesses seeking an affordable yet reliable bottling solution.

5.User-Friendly Interface

The easy-to-use control panel provides operators with complete control over the production process, making adjustments simple and real-time monitoring a breeze.

6.Durable and Reliable

Built with high-quality materials, this production line is durable and designed to withstand the demands of continuous, high-volume production.

7.Optimized for Energy Drinks

Specially engineered for energy drink production, the MIC 12-1 system ensures that the unique requirements of these beverages, such as carbonation and viscosity, are handled with precision.

8.Sustainable and Energy-Efficient

The production line is designed to minimize energy consumption, contributing to lower operational costs and a more environmentally friendly production process.

With the MIC 12-1 energy drink production line, Jiangsu Mic Machinery offers a robust, efficient, and flexible solution for businesses in the beverage industry. Whether you are producing energy drinks, soft drinks, or other beverages, our system provides the performance, reliability, and scalability needed to optimize your production capabilities and drive business growth.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |