MIC Semi Automatic Soft Drink Filling Machine ( 200-800BPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer specializing in the design and production of high-quality beverage filling and packaging equipment. With years of experience and a reputation for excellence, we are committed to providing innovative solutions tailored to the needs of the beverage industry. Our advanced machinery, including the MIC semi automatic soft drink filling machine, is designed to help businesses achieve efficient and reliable production. Whether you are a small-scale manufacturer or an established enterprise, Jiangsu Mic Machinery is your trusted partner for growth and success.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

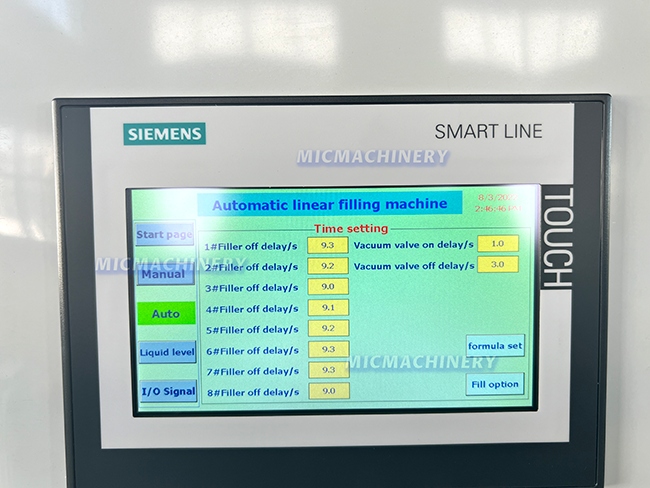

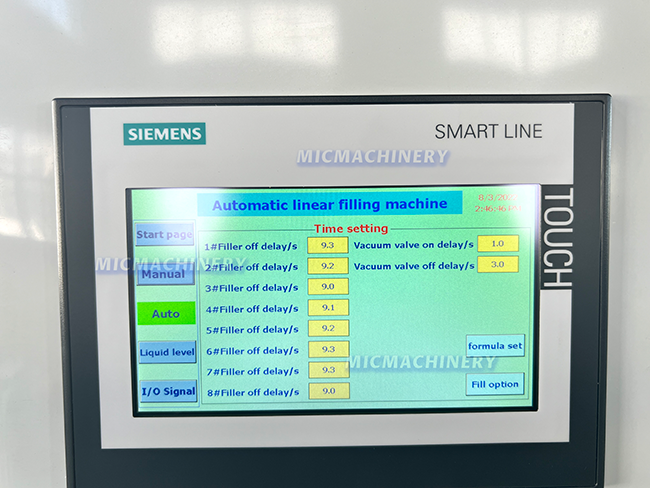

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of Soft Drink Filling Machine

The MIC semi automatic soft drink filling machine operates with a focus on precision and efficiency, ensuring consistent and high-quality output. The process begins with operators manually positioning the empty bottles on the filling platform. Once the bottles are in place, the filling process is initiated through a user-friendly control system.

The machine uses an isobaric filling system to maintain equal pressure between the beverage tank and the bottles, preserving the carbonation and ensuring uniform filling. This advanced mechanism reduces foam formation and minimizes product wastage. After filling, the bottles are manually transferred to the capping section, where they are securely sealed to maintain freshness and prevent leaks.

This semi-automatic design provides a perfect balance between manual operation and automation, making the MIC soft drink filling machine ideal for businesses requiring precision and control in their production processes.

Function

The MIC soft drink packing machine is specifically designed for the efficient filling of carbonated beverages such as soda, sparkling water, and other fizzy drinks. Key functions of this machine include:

Precision Filling: The isobaric filling mechanism ensures that each bottle is filled to the desired level while maintaining carbonation.

Compatibility: The machine is suitable for various bottle sizes and materials, including PET and glass.

User-Friendly Operation: Operators can easily control the filling process using the intuitive control panel.

Hygienic Processing: The machine is constructed with food-grade stainless steel, ensuring compliance with hygiene standards.

The MIC semi automatic soft drink filling machine streamlines production while maintaining the highest quality standards, making it an essential tool for small to medium-scale beverage manufacturers.

Advantages of Soft Drink Filling Machine

1、Cost-Effective Solution

The MIC soft drink filling machine offers exceptional performance at an affordable cost, making it an ideal choice for businesses looking to optimize their budget.

2、Preserves Carbonation

The isobaric filling system ensures that the carbonation levels of beverages remain intact, delivering a consistent and high-quality product.

3、Versatile Design

This machine is compatible with a wide range of carbonated beverages and accommodates different bottle sizes and shapes, offering maximum flexibility.

4、Compact and Space-Saving

Its compact design makes it suitable for facilities with limited floor space without compromising on efficiency.

5、Durability and Reliability

Built with robust materials, the MIC soft drink packing machine requires minimal maintenance, reducing downtime and operational costs.

6、Easy Operation

The semi-automatic design allows operators to control key production steps, ensuring greater flexibility and precision during filling.

7、Scalability

This machine is ideal for growing businesses, as it can be seamlessly integrated into larger production lines as production needs increase.

The MIC semi automatic soft drink filling machine embodies Jiangsu Mic Machinery's commitment to innovation, efficiency, and quality. Designed to meet the unique demands of the beverage industry, this machine is an excellent choice for manufacturers aiming to enhance their production processes. Contact us today to learn how this machine can transform your operations and help your business succeed.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |