MIC Semi Automatic Soft Drink Can Sealing Machine (30CPM)

MIC Semi Automatic Soft Drink Can Sealing Machine

Mic Machinery is a professional manufacturer specializing in advanced beverage packaging equipment. With years of innovation and technical expertise, we provide tailored machinery solutions for the food and beverage industry. Our product range includes high-performance fillers, cappers, and sealing machines built for durability, efficiency, and accuracy. Among our core products, the MIC Semi Automatic Soft Drink Can Sealing Machine is widely trusted for small to medium-sized production lines across the globe.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

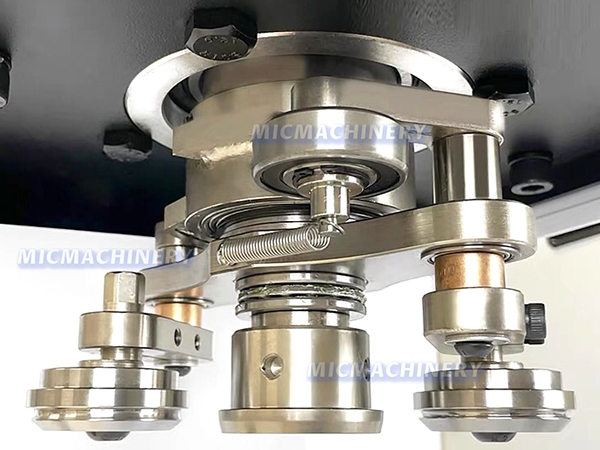

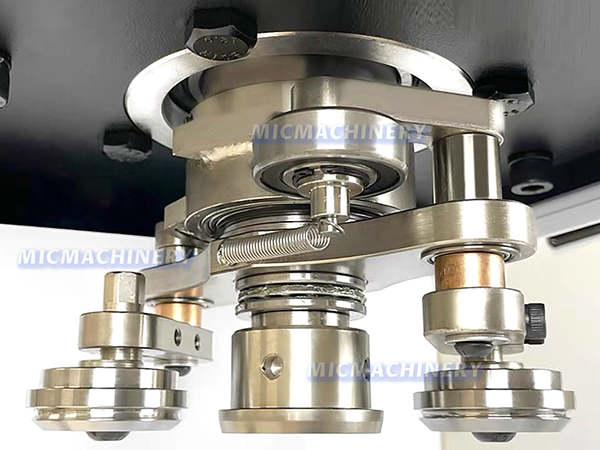

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

1)Manual Can Placement

The operator manually places the pre-filled can (usually filled by a soft drink can filling machine) onto the machine’s base platform.

2)Lid Positioning

An aluminum lid is manually placed on top of the can, aligning it precisely before sealing begins.

3)Can Elevation

By pressing a foot pedal or button, a pneumatic cylinder lifts the can toward the sealing head.

4)Rotary Sealing Action

As the can rotates, the sealing rollers move inward, applying controlled pressure to curl and seal the lid tightly onto the can.

5)Seal Completion and Release

Once sealing is complete, the machine lowers the can back to the base. The operator then removes the sealed can for the next production step.

Features and Advantages

This machine is designed to meet the operational needs of growing beverage businesses. Key features include:

▪ User-Friendly Interface: Simple operation with minimal training required.

▪ High Sealing Accuracy: Ensures leak-proof and tamper-evident seals.

▪ Compact Structure: Saves space while maintaining industrial performance.

▪ Durable Components: Built with stainless steel for hygiene and long life.

▪ Compatibility: Seamlessly pairs with a Can filling machine for soft drinks for integrated workflow.

Applications

The MIC Semi Automatic Soft Drink Can Sealing Machine is ideal for carbonated soft drinks, soda water, sparkling beverages, energy drinks, and more. It is commonly used in small beverage factories, pilot production labs, and specialty drink startups. When paired with a soft drink can filling machine, it forms an effective solution for complete canning lines, enabling efficient beverage production from start to finish.

Conclusion

If you're looking for a cost-effective, dependable sealing solution, the MIC Semi Automatic Soft Drink Can Sealing Machine offers the perfect balance between performance and flexibility. Combined with a Can filling machine for soft drinks, it enables streamlined production while maintaining high product quality. Mic Machinery is committed to supporting your beverage business with innovative, reliable packaging solutions.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 30 cans each minute |