MIC Semi Automatic Soda Filling and Capping Machine (200-800CPH)

MIC Semi Automatic Soda Filling and Capping Machine

Company Introduction

Jiangsu Mic Machinery is a trusted leader in the beverage filling and packaging industry, offering cutting-edge solutions designed to enhance efficiency and quality. Our range of products includes advanced soda filling equipment tailored to meet the diverse needs of beverage manufacturers. At Jiangsu Mic Machinery, we are committed to innovation, precision engineering, and exceptional customer service, ensuring that our clients have access to reliable and high-performance machinery, such as the MIC Semi Automatic soda filling and capping machine.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

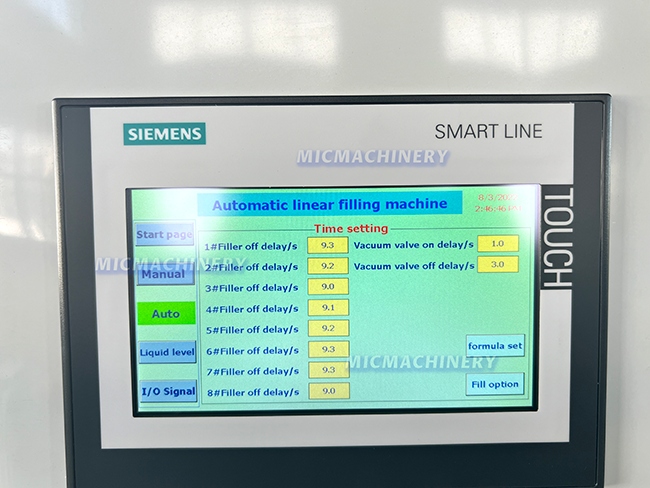

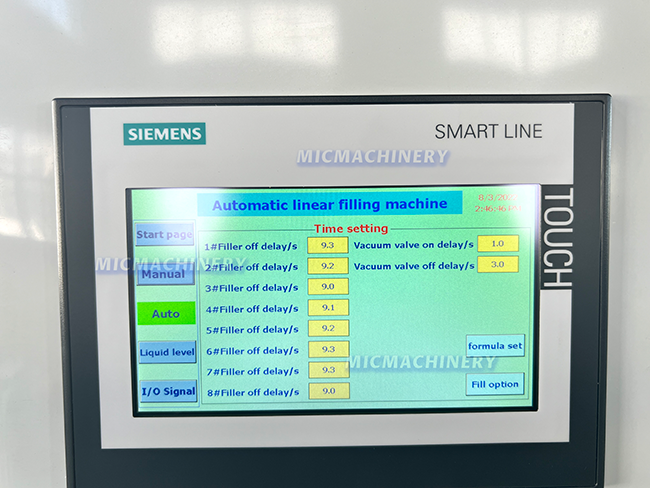

control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of Soda Filling Machine

The MIC Semi Automatic soda filling and capping machine operates using a semi-automated process that combines efficiency and precision. Bottles are manually placed onto the platform, where the soda filling system ensures accurate filling using pressure-filling technology. This process maintains carbonation levels while preventing spillage.

After filling, the bottles are capped using a semi-automatic mechanism that ensures a secure and airtight seal. The operator can control the pace of the process, allowing for flexibility and adaptability to different production requirements. This precise yet straightforward operation makes it an excellent choice for small to medium-scale beverage producers.

Function

The primary function of the MIC Semi Automatic soda filling and capping machine is to facilitate the efficient production of carbonated beverages while maintaining high-quality standards. The soda filling equipment is designed to:

Accurately fill soda, sparkling water, and other carbonated beverages into bottles.

Maintain carbonation and minimize product wastage during the filling process.

Cap bottles securely to preserve product integrity and extend shelf life.

Adapt to various bottle types and sizes, making it versatile for different packaging needs.

Advantages of Soda Filling Machine

The MIC Semi Automatic soda filling and capping machine offers several advantages that set it apart as a reliable choice for beverage production:

1、Cost-Effective Solution

This machine provides an affordable alternative to fully automated systems without compromising on performance.

2、Efficient Operation

The soda filling system delivers consistent and precise filling, ensuring high-quality output.

3、User-Friendly Design

Its intuitive operation requires minimal training, making it accessible for operators at all skill levels.

4、Versatility

The machine is compatible with a wide range of bottle shapes and sizes, offering flexibility for various production lines.

5、Compact Structure

Its space-saving design is ideal for smaller production facilities or businesses with limited floor space.

6、Durability

Built with high-quality materials, the machine ensures long-lasting performance and reliability.

The MIC Semi Automatic soda filling and capping machine is an excellent solution for businesses looking to streamline their production process while maintaining control and flexibility. With its robust features and professional design, it ensures efficient and high-quality soda production, making it a valuable asset for any beverage manufacturer.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |