MIC Semi Automatic Soda Bottling Plant Machine (Speed 200-800BPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of cutting-edge bottling and packaging machinery, serving the beverage industry with innovative solutions that optimize production efficiency. With years of industry experience, we have built a reputation for producing high-quality equipment designed to meet the ever-evolving needs of beverage producers worldwide. Our commitment to precision, innovation, and customer satisfaction ensures that each machine we design offers reliable performance and meets the highest standards of production.

Our MIC Semi-Automatic soda bottling plant machine is an excellent choice for businesses looking to enhance their production capabilities while maintaining flexibility. Perfect for small to medium-sized operations, this machine provides an affordable, efficient solution for bottling soda into glass bottles at speeds ranging from 200 to 800 bottles per hour. Engineered with durability and precision in mind, this machine offers an excellent balance of automation and manual operation, providing an ideal solution for businesses that may not require fully automated systems but still want high-quality performance.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

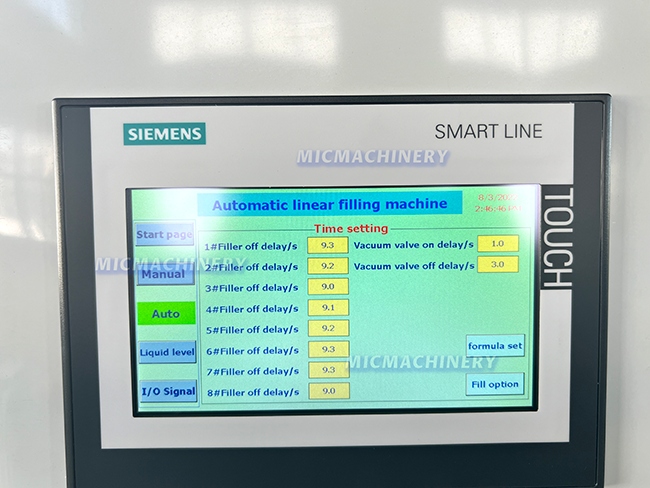

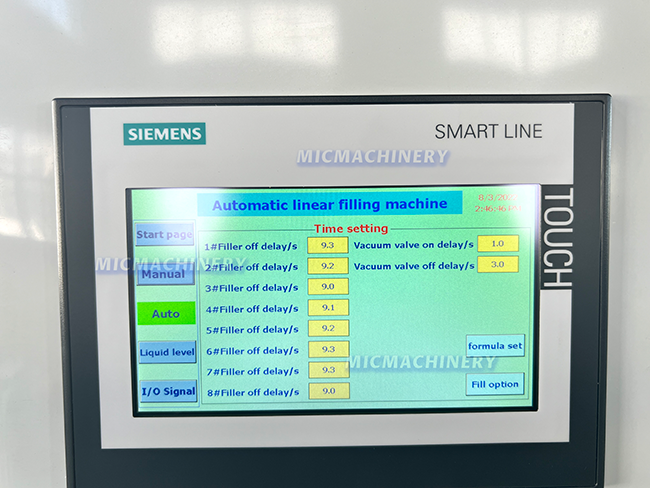

control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of Soda Bottling Machine

The MIC Semi-Automatic soda bottling plant machine is designed to streamline the bottling process by automating the majority of operations, while still allowing operators to maintain control over certain aspects of the process. The machine’s system consists of three primary stages: rinsing, filling, and capping.

Rinsing:The process begins with the automatic rinsing of glass bottles. Bottles are loaded onto the machine, and the glass bottle soda filling machine utilizes an integrated rinsing system to clean each bottle thoroughly before filling. This step is critical to maintaining hygiene standards and ensuring that the bottles are free from contaminants.

Filling: The next stage is the filling process. The soda bottling machine uses a precise filling valve to fill each glass bottle with soda to the desired level. The semi-automatic design allows the operator to manage the filling process, making minor adjustments if necessary, while the machine ensures accurate filling for each bottle.

Capping: The final step is the capping process, where the soda bottling plant machine securely seals each bottle. The capping is semi-automated, with the operator placing the caps on the bottles before the machine tightens them. This design ensures that each bottle is sealed properly, preventing leaks and ensuring the carbonation of the soda is maintained.

The combination of automated and manual control elements in this soda bottling machine provides flexibility, making it ideal for businesses that require moderate production capacity while still benefiting from automation.

Advantages of MIC Semi-Automatic Soda Bottling Plant Machine

1、Cost-Effective Solution

One of the key advantages of the MIC Semi-Automatic soda bottling plant machine is its affordability. With a moderate production speed of 200 to 800 bottles per hour, it offers an excellent solution for small to medium-sized beverage manufacturers who want high-quality performance without the significant investment required for fully automated systems.

2、Flexibility in Operations

The semi-automatic nature of the soda bottling machine allows operators to have more control over the production process, making it easier to adjust filling and capping settings as needed. This provides greater flexibility, especially when bottling different bottle sizes or types of soda.

3、Compact and Space-Saving Design

Unlike larger, fully automated bottling lines, the soda bottling plant machine has a more compact footprint, making it a great option for facilities with limited space. It combines essential functions such as rinsing, filling, and capping in a single machine, reducing the need for additional equipment and saving valuable production floor space.

4、Hygiene and Product Quality

Maintaining product quality and hygiene is crucial in beverage production, and this machine is designed to ensure both. The glass bottle soda filling machine uses high-quality materials and is easy to clean and maintain. The rinsing system guarantees that each bottle is sanitized before filling, preventing contamination and ensuring that each batch of soda meets strict hygiene standards.

5、Enhanced Productivity

The MIC Semi-Automatic soda bottling plant machine increases productivity by automating essential tasks like rinsing, filling, and capping. Although it requires some manual intervention, the machine’s semi-automatic design speeds up the process and improves consistency, allowing operators to focus on other important tasks while ensuring smooth production.

6、Easy Maintenance and Operation

This machine is designed for easy maintenance and operation. With simple controls and intuitive features, operators can quickly become proficient in running the system. Additionally, the machine’s components are accessible, making routine maintenance tasks easier and helping to minimize downtime.

7、Reliable Performance

Despite being a semi-automatic system, the machine provides dependable, consistent performance, ensuring high-quality filling and capping with minimal downtime. Its robust design is built to handle the challenges of continuous production, making it a reliable choice for any soda bottling plant.

Conclusion

The MIC Semi-Automatic soda bottling plant machine offers a reliable and cost-effective solution for businesses looking to improve their soda bottling processes. With its semi-automatic design, it strikes the perfect balance between automation and manual control, making it ideal for small to medium-sized operations that require flexibility and efficiency. Featuring high-speed rinsing, filling, and capping, the machine is designed to maintain high product quality and hygiene standards while reducing operational costs. Contact Jiangsu Mic Machinery today to learn more about how our soda bottling plant machine can improve your bottling processes and help your business grow.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |