MIC Semi-Automatic Small Carbonated Drink Sealing Machine (30CPM)

MIC Semi-Automatic Small Carbonated Drink Sealing Machine

Mic Machinery is a professional manufacturer committed to designing and producing advanced packaging solutions for the beverage industry. Our company specializes in small- to mid-scale production systems that prioritize precision, durability, and efficiency. With years of expertise, we offer reliable machines such as the small carbonated drink sealing machine, widely adopted in the global market for soda and sparkling beverage packaging.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

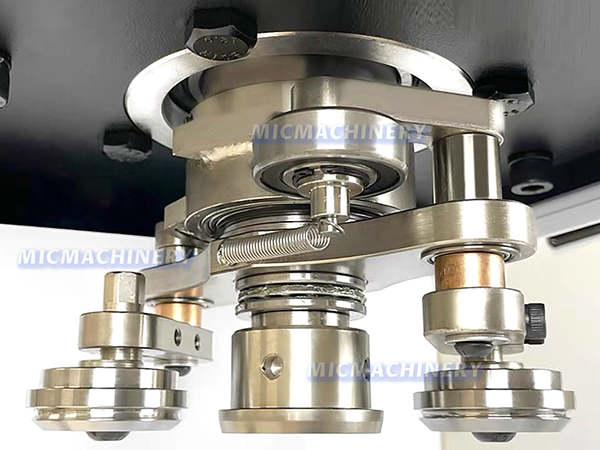

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi-Automatic Small Carbonated Drink Sealing Machine operates through a streamlined manual-assisted sealing process designed for ease of use and consistent results. Here's how it works:

1)Manual Can Placement – The operator places the filled carbonated drink can on the base platform.

2)Lid Positioning – A pre-scored aluminum lid is manually placed on top of the can.

3)Clamping – The machine clamps and aligns the can and lid for proper sealing.

4)Sealing Operation – The rotary sealing head activates, creating a tight and reliable seal.

5)Release – The sealed can is unclamped and removed, ready for distribution or further packaging.

This process maintains carbonation levels while ensuring high sealing integrity.

Functional Advantages

This small carbonated drink sealing machine is compact, user-friendly, and built with stainless steel for long-lasting performance. Key benefits include:

▪ Compatible with various can diameters and heights

▪ Precise mechanical operation with minimal maintenance

▪ Designed to work seamlessly with a carbonated drink filling machine

▪ Ideal for limited spaces or mobile production environments

▪ Affordable solution for craft and pilot-scale beverage producers

▪ Can seal up to 20–30 cans per minute depending on operator speed

The machine balances ease of use with professional-grade functionality.

Applications

The MIC Semi-Automatic Small Carbonated Drink Sealing Machine is suitable for craft soda makers, small beverage factories, and test laboratories. When combined with a carbonated drink filling machine or integrated into a full carbonated drink filling equipment line, it creates a reliable packaging solution for soda, sparkling water, kombucha, and flavored carbonated beverages. It’s particularly effective for start-ups or small brands focused on local distribution.

Conclusion

The MIC Semi-Automatic Small Carbonated Drink Sealing Machine offers an excellent choice for small beverage businesses looking for efficient, space-saving, and accurate can sealing. In combination with carbonated drink filling equipment, it enhances production quality while keeping operational complexity low. Choose Mic Machinery for a trusted and scalable packaging solution.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 30 cans each minute |