MIC Semi Automatic Drink Bottling Line (Speed 200-800BPH)

MIC Semi Automatic Drink Bottling Line

Jiangsu Mic Machinery is a leading manufacturer of high-performance bottling solutions for the beverage industry. With a focus on efficiency and quality, we design and produce machinery that meets the diverse needs of our clients. Our MIC Semi Automatic Drink Bottling Line is engineered to deliver flexibility and precision, making it an ideal choice for small to medium-scale beverage manufacturers.

At Jiangsu Mic Machinery, we are committed to providing cutting-edge bottling solutions that enhance production efficiency while maintaining exceptional product quality.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

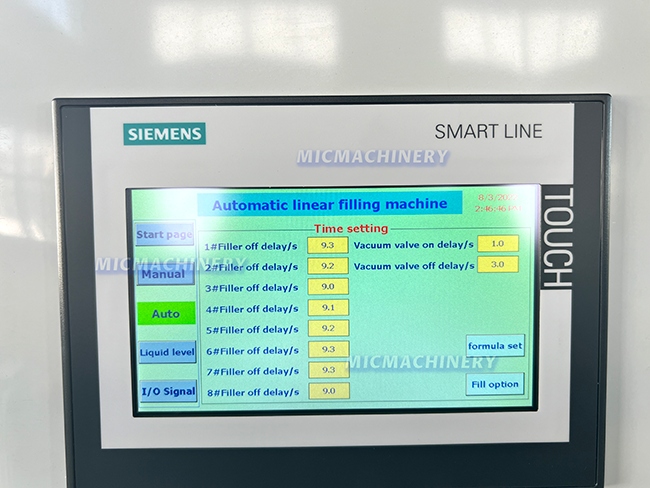

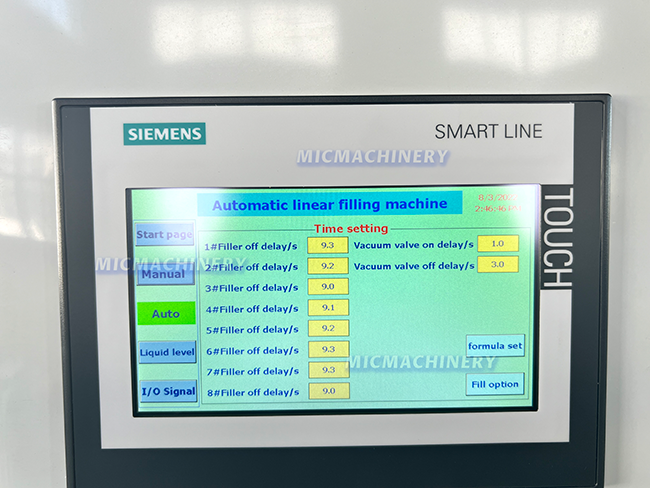

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of the Drink Bottling Machine

The MIC Semi Automatic Drink Bottling Line operates with precision to ensure smooth and effective bottling processes. The machine features several key steps that ensure accuracy and quality:

Filling: The drink bottles are filled using a highly accurate filling system, which minimizes wastage and ensures that every bottle contains the right amount of liquid.

Capping: After filling, the bottles move to the capping station where they are securely sealed to prevent leakage and contamination, ensuring product integrity.

Packaging: Once capped, the bottles are transferred to the packaging section, where they are packed efficiently into crates or boxes for easy transport.

This semi-automated system allows for manual control over the loading and unloading of bottles while automating the filling, capping, and packaging stages for optimal efficiency. Whether you are bottling soft drinks, juices, or water, this drink bottling machine provides precision and consistency in every bottle.

Function of the Drink Bottling Machine

The MIC Semi Automatic Drink Bottling Line is designed to handle various functions that are essential to beverage production:

Filling Variety: It can accommodate different beverage types, including soft drinks, juices, and non-carbonated beverages. This versatility makes it an ideal choice for businesses offering a range of products.

Precision Capping: The machine features an automated capping process that guarantees the bottles are tightly sealed, preserving the freshness and quality of the beverage.

Semi-Automated Workflow: The machine allows for manual intervention where needed while automating key processes, offering flexibility in production speeds based on demand.

Compact Design: Its compact design makes it easy to install in smaller spaces, making it an excellent choice for facilities with limited floor space.

Advantages of the Drink Bottling Machine

The MIC Semi Automatic Drink Bottling Line offers several advantages for businesses in the beverage industry:

1、Cost-Efficiency

The semi-automatic nature of the machine reduces initial investment costs while maintaining high efficiency, making it an excellent choice for smaller-scale producers.

2、Consistency

The precise filling and capping systems ensure consistent product quality, which helps build customer trust and loyalty. This is particularly important when bottling soft drinks or other liquid beverages that require precision.

3、Flexibility

The semi-automated operation provides flexibility in production speeds, which is ideal for businesses with fluctuating demand or production needs. Whether you need a high-output soft drink bottling machine or a more tailored system, this machine adapts to your requirements.

4、Reduced Labor Costs

By automating key processes, the machine reduces the need for manual labor, which in turn cuts down on labor costs and improves efficiency.

5、Ease of Use

The user-friendly interface ensures that operators can quickly get up to speed and maintain smooth operations with minimal training.

6、Scalability

As your production needs grow, the system can be easily upgraded to accommodate higher volumes, making it a scalable solution for expanding businesses.

Energy Efficiency

The machine is designed to operate efficiently, consuming less energy while maintaining high performance, which helps reduce operational costs.

Conclusion

The MIC Semi Automatic Drink Bottling Line offers a cost-effective, flexible, and efficient solution for businesses looking to streamline their beverage production process. With its focus on precision and user-friendly operation, this machine helps businesses maintain high-quality standards while reducing operational costs.

At Jiangsu Mic Machinery, we are committed to providing top-of-the-line bottling solutions that help businesses succeed. The MIC Semi Automatic Drink Bottling Line is just one example of our dedication to innovation and customer satisfaction.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |