MIC Semi Automatic Beverage Bottling Equipment (Speed 200-800BPH)

Introduction to MIC Semi-Automatic Beverage Bottling Equipment

At Jiangsu Mic Machinery, we specialize in designing and manufacturing high-performance beverage bottling equipment that is trusted by beverage producers around the world. With years of experience in the industry, we are committed to providing innovative and efficient bottling solutions. Our MIC Semi-Automatic beverage bottling machine is a versatile, cost-effective solution for small to medium-scale beverage production lines. Whether you're bottling juices, flavored water, or carbonated drinks, our machine ensures the highest standards of quality, reliability, and efficiency.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

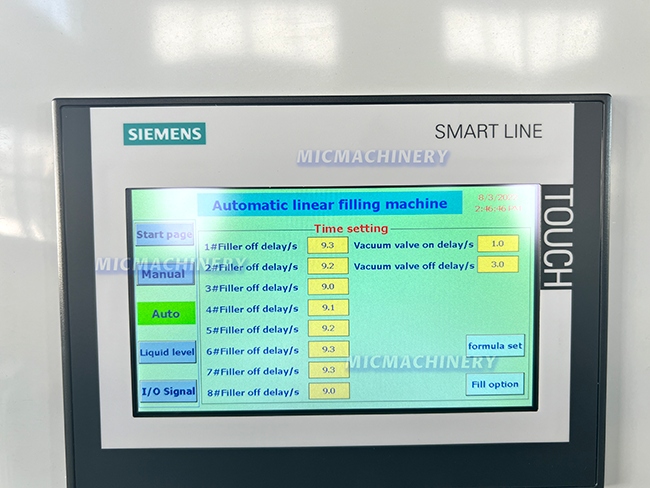

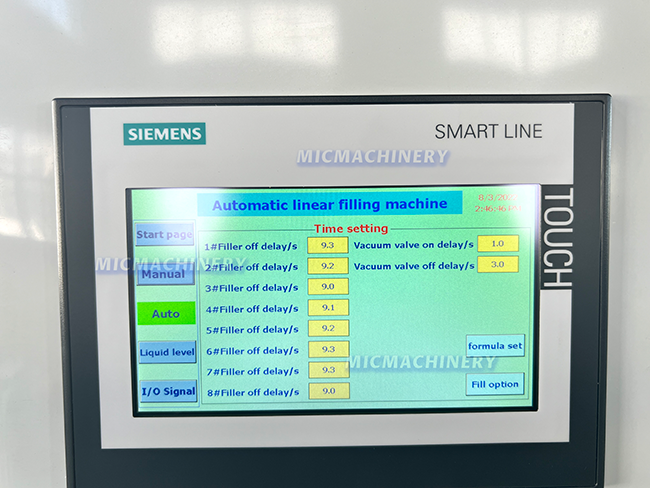

control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of the Beverage Bottling Machine

The MIC Semi-Automatic beverage bottling machine operates with a seamless integration of automation and manual processes, offering an efficient yet flexible solution for beverage production. The key working components include:

1)Filling Process

The beverage bottle filling machine is equipped with an advanced filling system that uses gravity or pressure filling methods to ensure precise and consistent filling. The system is capable of handling various beverage types, ensuring that the filling process does not cause spillage or wastage. For carbonated beverages, the machine incorporates features to preserve carbonation, keeping the product fresh and effervescent.

2)Capping Mechanism

Once the bottles are filled, they proceed to the capping station where the semi-automatic system applies caps securely to each bottle. The capping system is designed to work with a variety of bottle types and cap sizes, ensuring tight and reliable seals to prevent leaks and maintain beverage quality.

3)Operator Role

The semi-automatic nature of the machine means that while the filling and capping processes are automated, operators play a key role in placing and removing bottles from the machine. This provides flexibility for small-scale operations while maintaining efficient production speeds.

4)Control Panel

The user-friendly control panel allows operators to adjust settings, including fill volume, bottle types, and production speeds. The simple interface ensures that operators can make adjustments with ease, minimizing downtime and ensuring smooth transitions between different production runs.

Function of the Beverage Bottling Machine

The MIC Semi-Automatic beverage bottling machine is designed to deliver precise, reliable, and consistent results across various beverage products. Some of the core functions include:

Accurate Filling: The machine ensures precise filling levels, avoiding overfill or underfill and optimizing product yield. It is adaptable to different bottle shapes and sizes, making it a versatile choice for businesses with varied packaging requirements.

Automatic Capping: The machine automatically applies caps after filling, ensuring secure seals. This reduces the potential for contamination and leakage, maintaining the product's freshness and extending its shelf life.

Versatile Application: The system can handle a range of beverage types, including still and carbonated drinks, with easy adjustments for different viscosity levels and carbonation pressures.

Efficient Production: The combination of automated filling and capping with manual bottle placement ensures that production runs are efficient and streamlined. The system maximizes throughput while minimizing operator involvement, reducing labor costs.

Compact Design: The semi-automatic design is compact, making it a great choice for smaller production spaces without sacrificing efficiency. It’s a practical solution for manufacturers looking for high-quality bottling equipment without the need for large-scale machinery.

Advantages of the Beverage Bottling Machine

The MIC Semi-Automatic beverage bottling machine offers several advantages that enhance its appeal to beverage manufacturers:

1、Cost-Effective

Compared to fully automatic systems, the semi-automatic design is more affordable, making it an excellent option for smaller producers or businesses that require flexibility in their bottling operations. The beverage bottling equipment strikes an ideal balance between automation and manual intervention.

2、Flexibility

The machine is adaptable to different types of bottles, caps, and beverage formulations. It is an excellent choice for companies that offer multiple product lines and require a system that can handle different packaging needs without the need for additional machinery.

3、Ease of Use

The user-friendly interface of the MIC Semi-Automatic beverage bottling machine allows operators to quickly adjust settings based on production requirements. Whether it’s adjusting the fill volume or switching bottle types, the machine’s controls are simple to navigate, minimizing training time and operational errors.

4、Increased Efficiency

By automating the filling and capping processes, the machine reduces labor time and human error. This leads to faster production cycles, enabling manufacturers to meet tight deadlines and increase their throughput. Its efficiency also reduces the potential for product waste, improving overall productivity.

5、Enhanced Product Quality

The precision of the filling and capping systems ensures that every bottle meets the required quality standards. The consistent fill levels and tight seals help maintain product integrity, which is crucial for preserving the taste, quality, and shelf life of the beverage.

6、Low Maintenance

The MIC Semi-Automatic beverage bottling machine is designed with easy maintenance in mind. Its robust construction ensures durability, while the modular design allows for quick and easy access to parts for routine cleaning and maintenance, minimizing downtime and extending the life of the equipment.

7、Compact and Space-Saving

The semi-automatic system’s compact design makes it ideal for operations with limited space. Despite its smaller footprint, the machine offers high throughput and exceptional performance, making it a great choice for businesses looking to optimize their available space without compromising on production efficiency.

Conclusion

The MIC Semi-Automatic beverage bottling machine from Jiangsu Mic Machinery is the perfect solution for small to medium-sized beverage manufacturers who seek high-quality, efficient, and cost-effective bottling equipment. With its precise filling, reliable capping, and user-friendly operation, it streamlines production while maintaining the highest product standards. Our beverage bottling equipment is designed to meet the growing demands of modern beverage production, ensuring that manufacturers can deliver exceptional products to consumers every time.

At Jiangsu Mic Machinery, we are committed to providing innovative solutions for the beverage industry. Our beverage bottle filling machine and beverage bottling equipment are built with quality and performance in mind, helping you optimize your production process while maintaining flexibility, efficiency, and reliability.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |