MIC 24-24-8 Bottled Water Production Line

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer specializing in advanced filling and packaging solutions for the beverage industry. With decades of expertise, we provide high-performance equipment that enhances efficiency and quality for bottling and packaging operations. Our state-of-the-art water bottling lines and water filling lines are designed to meet the ever-growing demands of the global market. We are committed to delivering innovative solutions that maximize productivity, reduce operational costs, and ensure optimal product quality. Whether you need a bottled water production line or other specialized equipment, Jiangsu Mic Machinery offers scalable and reliable systems built to suit your specific needs.

|

Control Panel The Control Panel with Water Filling Machine offers precise control over the filling process. With an intuitive interface, it ensures accurate volume measurement, efficient operation, and seamless automation for water bottling. |

|

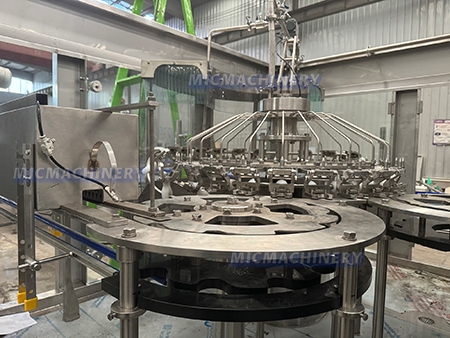

Filling Head The Filling Head with Water Filling Machine is designed to ensure precise and consistent filling of water bottles. Equipped with advanced technology, it minimizes spillage and ensures accurate volume measurement for each bottle. Ideal for high-speed, automated water bottling processes, it enhances efficiency and reduces downtime. |

|

Equipment Introduction

The MIC 24-24-8 Bottled Water Production Line is a fully automated system designed for high-efficiency water bottling operations. This advanced water filling line combines cutting-edge technology with user-friendly operation to streamline the entire process, from bottle rinsing to final packaging. Below are some key features of the bottled water production line:

High Capacity: The MIC 24-24-8 water bottling line is designed for high-capacity production, capable of handling large volumes of bottled water. With an impressive output rate, this line ensures fast and efficient production while maintaining top-quality standards.

2.Multi-Stage Process: The line is equipped with multiple stages to optimize each step of the filling process:

· Bottle Rinsing: Bottles are automatically rinsed to remove any contaminants, ensuring product safety and hygiene.

· Filling: The advanced volumetric filling technology precisely fills each bottle with water, maintaining accuracy and minimizing waste.

· Capping: After filling, the bottles are sealed with secure caps to maintain freshness and prevent contamination.

· Labeling: The bottles are labeled with high precision, offering clear and professional branding.

· Packaging: The final step involves automatic packaging, efficiently grouping bottles into cartons or other packaging materials for shipment.

3.Automation and Efficiency: The system is highly automated, reducing the need for manual intervention and streamlining the production process. This leads to faster production times and reduced labor costs.

4.Energy-Saving Features: With energy-efficient components, the water bottling line reduces overall energy consumption, helping businesses lower operational costs and increase sustainability.

5.User-Friendly Interface: The water filling line features an intuitive control panel, making it easy for operators to manage the production process and make adjustments as needed.

6.Durability and Reliability: Designed with high-quality materials and precision engineering, the MIC 24-24-8 line is built to withstand continuous operation, reducing downtime and maintenance costs.

7.Flexible Production: This line can accommodate various bottle sizes and production volumes, providing flexibility for businesses with diverse requirements. As demand increases, the system can be scaled up to meet higher production needs.

In summary, the MIC 24-24-8 Bottled Water Production Line offers a comprehensive and efficient solution for businesses looking to streamline their water bottling operations. With its high capacity, automation, and advanced technology, this line is designed to optimize productivity, reduce costs, and deliver high-quality results. Whether you're starting a new operation or upgrading your current systems, this water bottling line ensures reliable performance and scalability for long-term success.

|

Model |

|||

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |