MIC-150C Inline Can Labeler (Speed 9000BPH)

Introduction to the Inline Can Labeler

An inline can labeler is an essential piece of equipment for efficient and high-speed labeling in the beverage industry. Designed to handle a wide range of can sizes and types, this machine offers a streamlined solution for beer can labeling and other can labeling processes. Whether for craft brewers or large-scale production lines, the can labeling machine ensures precise and consistent label application, enhancing product presentation and brand identity.

Description of the Inline Can Labeler

The inline can labeler is engineered to integrate seamlessly into existing production lines, delivering high-speed labeling without compromising on accuracy. It is particularly popular for beer can labeling applications, where speed and precision are critical. This versatile can labeling machine can handle various can formats, ensuring that labels are applied smoothly and securely, reducing downtime and increasing overall productivity. With advanced technology, the inline can labeler can be customized to meet specific needs, offering flexibility for different types of labels, including self-adhesive and shrink sleeves. Perfect for both small batches and large-scale production, this labeling machine ensures that every can is properly labeled with minimal manual intervention.

|

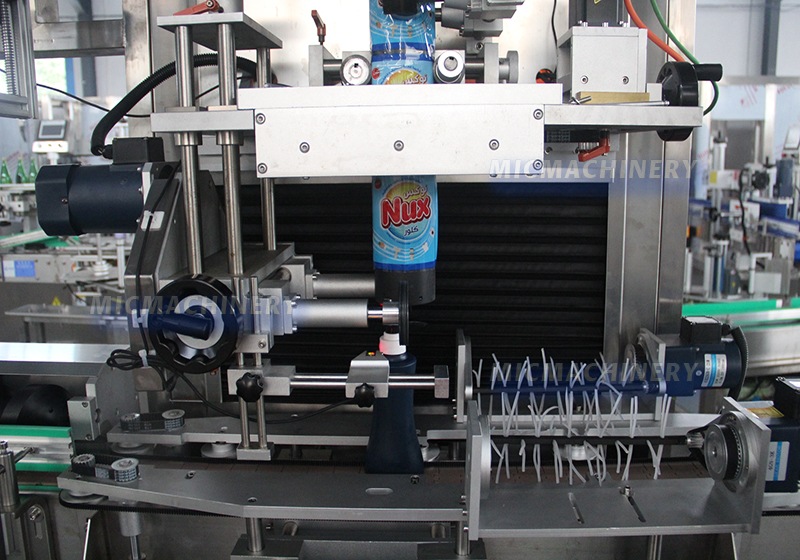

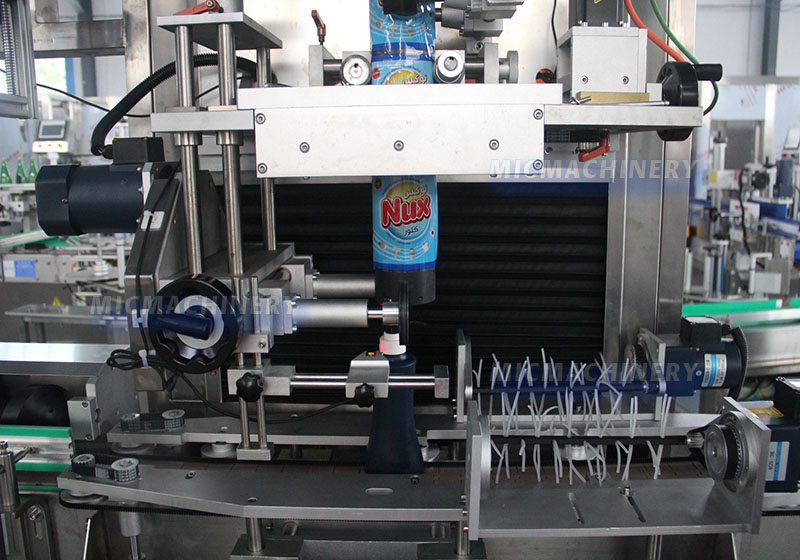

auto sleeving device

The auto sleeving device in a shrink sleeve labeling machine is a fully automated mechanism designed to accurately cut and apply shrink film sleeves onto containers at high speed. It operates by feeding sleeve material from a roll, precisely cutting it into individual sleeves, and seamlessly placing each sleeve over the bottle or container. This system ensures consistent positioning and alignment, making it ideal for bottles of various shapes and sizes. The auto sleeving device enhances production efficiency, reduces manual handling, and ensures smooth integration with the shrink tunnel for a tight, professional label finish. |

|

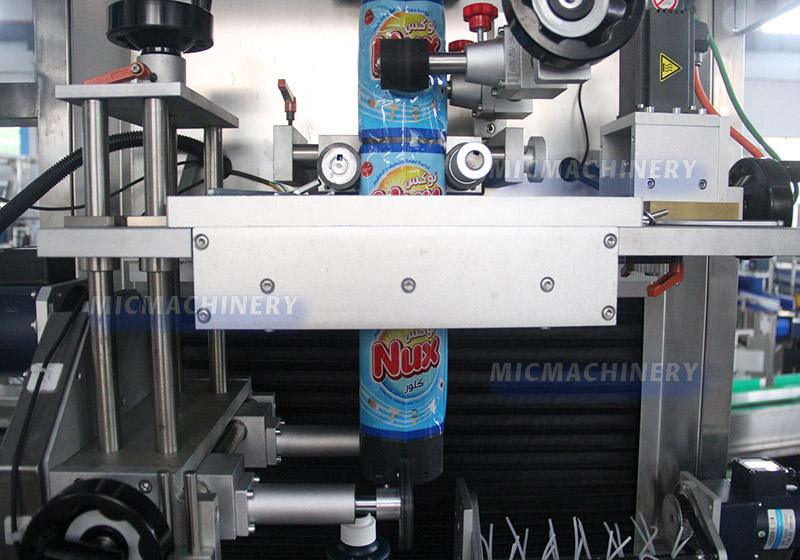

cutting blade unit

The cutting blade unit, also known as the cutter drum, is a core component of a shrink sleeve labeling machine responsible for precisely cutting the continuous sleeve film into individual labels. Equipped with high-speed rotary blades and driven by a servo motor, the cutter drum ensures clean, consistent cuts without tearing or misalignment. It works in perfect synchronization with the pulling wheel and sleeving device to maintain production accuracy at high speeds. Designed for durability and easy maintenance, the cutting blade unit supports various label materials and sleeve thicknesses, ensuring long-term stability and efficiency. |

|

|

pulling wheel

The pulling wheel in a shrink sleeve labeling machine plays a critical role in controlling the movement of the shrink film during the sleeving process. Positioned between the film unwind section and the cutting unit, the pulling wheel ensures smooth and stable film feeding by maintaining constant tension. This component precisely synchronizes with the cutter and sleeving system to deliver accurate label lengths and prevent film slippage or misalignment. Its durable, anti-slip surface and servo-driven control make it essential for high-speed, continuous labeling operations with consistent results. |

Sleever machines, also known as sleeving machines or sleeve labeling machines, are used in various industries to label and package products with shrinkable sleeves. These machines offer a range of benefits to manufacturers, including:

1.Versatility: Sleever machines can handle a variety of sleeve sizes and shapes, making them suitable for a wide range of products, from cans and bottles to jars and containers.

2. High speed and efficiency: These machines can apply sleeves at high speeds, which means faster production and higher output. Additionally, automated sleeving machines can reduce labor costs and improve overall efficiency.

3. Improved branding: Sleeve labeling allows for full-color, high-quality graphics, which can help products stand out on the shelf and improve brand recognition.

4. Tamper-evident packaging: Sleever machines can apply shrink sleeves that provide a tamper-evident seal, which helps ensure product safety and integrity.

5. Cost-effective: Sleever machines offer a cost-effective labeling solution compared to other labeling methods, such as pressure-sensitive labeling or in-mold labeling.

6. Environmental benefits: Sleeve labeling uses less material than other labeling methods, reducing waste and environmental impact. Additionally, some sleeve materials can be recycled or made from biodegradable materials.

Overall, sleever machines provide manufacturers with an efficient and cost-effective solution for labeling and packaging products. The versatility, speed, and branding benefits make them a popular choice for companies looking to improve their packaging processes.

| Host machine | AC220V, 50/60HZ, 3KW, single-phase |

| Production speed | 9000 b/h as 100mm label |

| Standard length | The standard length of label is 300mm and the speed can be adjusted accord to customer's requirements. The speed will be faster if the label is shorter. |

| Diameter of bottle body | φ40mm-φ100mm |

| Length of label | 100mm |

| Thickness of label | 0.045mm |

| Material of label | PVC、PET、 OPS |