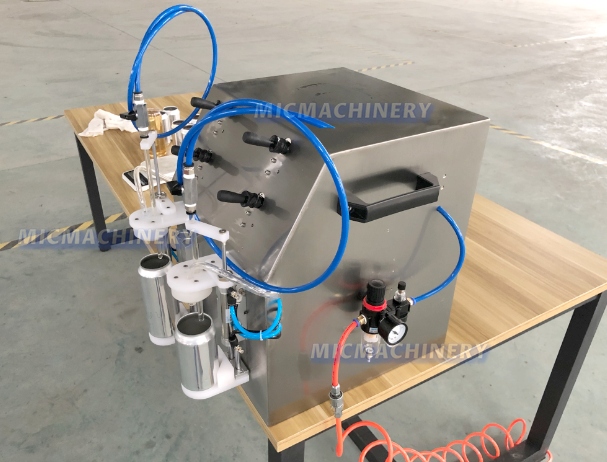

MIC Manual Soft Drink Can Filling Machine (8CPM)

Company Introduction

Jiangsu Mic Machinery is a trusted leader in manufacturing high-quality beverage production equipment. With years of expertise and innovation, we specialize in providing efficient, reliable, and tailored solutions to meet the diverse needs of beverage manufacturers worldwide. Our machines are engineered with precision, ensuring optimal performance and compliance with global industry standards. The MIC Manual soft drink can filling machine exemplifies our commitment to quality and innovation, offering small-scale producers an affordable and effective solution for their canning operations.

|

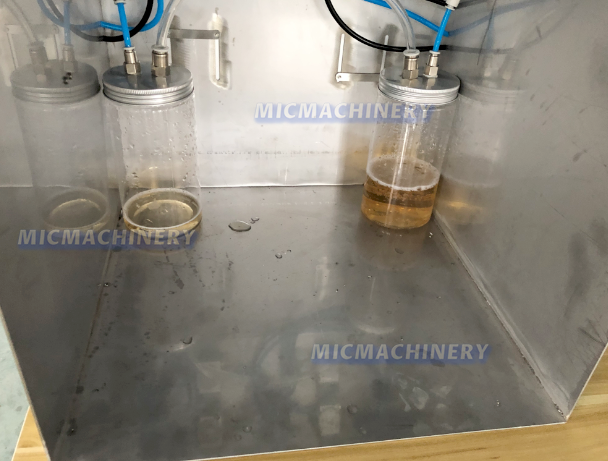

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Features of Soft Drink Canning Machine

The MIC Manual soft drink canning machine is designed with essential features to provide exceptional performance for small and medium-scale soft drink producers. Key features include:

Manual Operation with Precision Control: This machine allows operators to fill cans manually with exceptional accuracy, ensuring consistent product quality.

Compact and Space-Saving Design: The lightweight and compact structure make it ideal for operations with limited space, ensuring portability and flexibility.

Versatility in Can Sizes: It is compatible with a range of can sizes, enabling the filling of different types of soft drink tin can filling machine requirements.

Preservation of Carbonation: Designed to maintain the carbonation level of soft drinks during the filling process, ensuring product freshness and quality.

Food-Grade Materials: Built with stainless steel and other food-grade materials, the machine guarantees hygiene and durability.

Ease of Maintenance: With a simple structure and fewer moving parts, it is easy to clean and maintain, reducing downtime and operational costs.

Advantages of Soft Drink Canning Machine

The MIC Manual soft drink can filling machine offers multiple benefits that make it a cost-effective and efficient choice for businesses:

1)Cost-Effective Solution: This manual machine is perfect for small-scale operations, offering high performance at a lower initial investment.

2)Simple and User-Friendly Design: Its straightforward operation minimizes training requirements, making it easy to use for operators of all skill levels.

3)Accurate Filling Process: The machine ensures consistent and precise filling, minimizing product wastage and maximizing profitability.

4)Enhanced Durability: Made from robust materials, the soft drink canning machine is built to withstand frequent use while maintaining reliability.

5)Customizable Features: Jiangsu Mic Machinery provides customization options, allowing the machine to meet specific operational needs.

6)Environmentally Friendly: Designed to operate with minimal energy consumption, this soft drink tin can filling machine supports eco-friendly manufacturing practices.

7)Scalable for Growth: The manual machine is ideal for startups and small-scale businesses, offering an affordable solution that can scale as production needs grow.

At Jiangsu Mic Machinery, we are dedicated to providing high-quality beverage machinery that meets the needs of diverse industries. The MIC Manual soft drink canning machine is a reliable and efficient solution for businesses looking to maintain product quality while optimizing their production process.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |