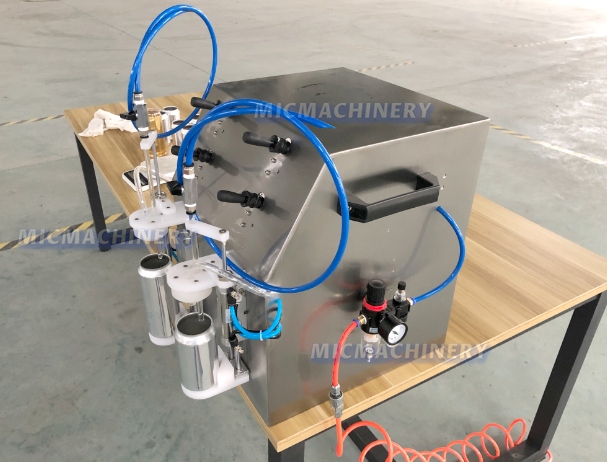

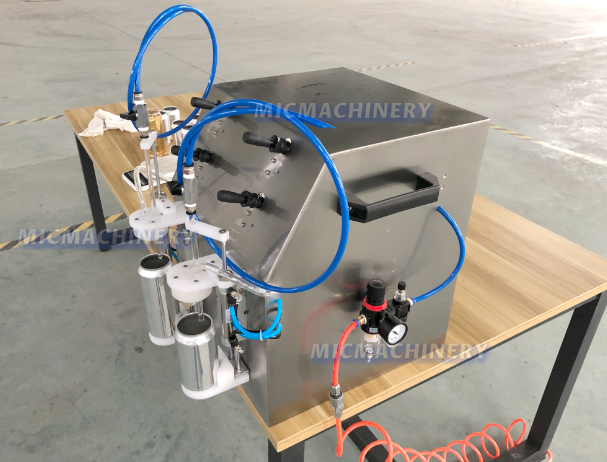

MIC Manual Soda Filling Machine (8 cans per minute)

MIC Manual Soda Filling Machine

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer specializing in innovative beverage filling and packaging equipment. With years of experience and expertise, we are dedicated to delivering high-quality machinery tailored to meet the unique requirements of our clients. From small-scale operations to large production facilities, our products, including the manual soda filling machine, are designed to ensure precision, efficiency, and reliability.

|

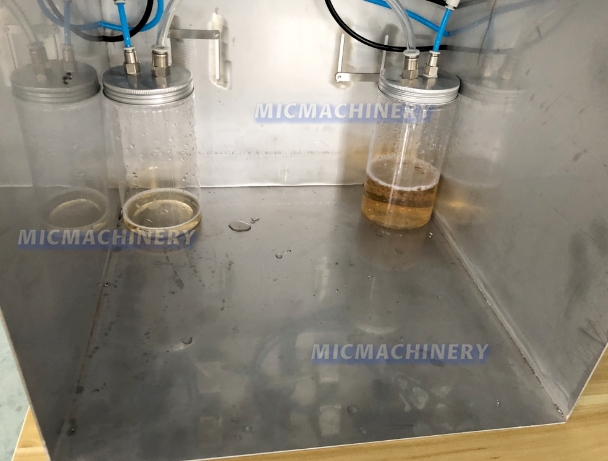

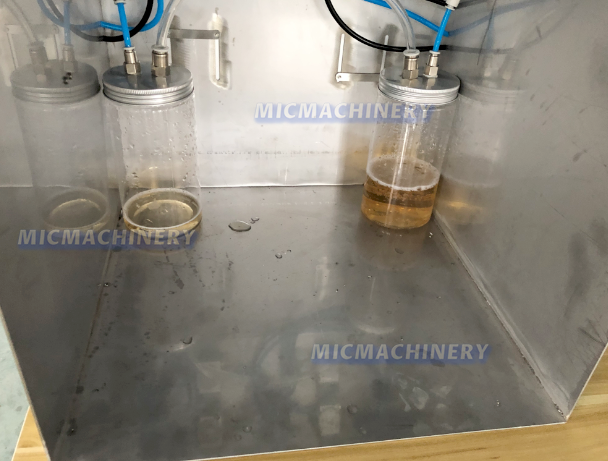

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Features of Soda Filling Machine

The MIC manual soda filling machine offers a range of features designed to streamline small-scale beverage production. Key features include:

Efficient Filling Mechanism: The soda filling system ensures precise and consistent filling, maintaining carbonation levels and minimizing waste.

Compact Design: This machine's lightweight and space-saving structure make it ideal for smaller facilities or startups.

Versatile Compatibility: The machine accommodates various bottle types and sizes, offering flexibility for different product lines.

Durable Construction: Built with robust materials, the soda filling and capping machine is designed for longevity and reliability.

User-Friendly Operation: Its manual controls are intuitive, requiring minimal training for efficient operation.

Advantages of Soda Filling Machine

The MIC manual soda filling machine is a practical solution for businesses looking to optimize their production process. Its benefits include:

1、Cost-Effectiveness

As a manual machine, it offers a more affordable option for startups and small-scale producers without compromising on performance.

2、Precision and Control

The soda filling system enables operators to manage the filling process with exceptional accuracy, ensuring consistent product quality.

3、Low Maintenance

The simple design reduces maintenance requirements, saving time and operational costs.

4、Adaptability

Suitable for filling a wide range of carbonated beverages, the machine supports versatile production needs.

Compact and Portable

Its portable design makes it easy to transport and integrate into various production setups.

The MIC manual soda filling machine is a reliable choice for small-scale beverage manufacturers seeking precision and quality in their production lines. With its durable design, versatile functionality, and efficient operation, it is a valuable addition to any soda production setup.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |