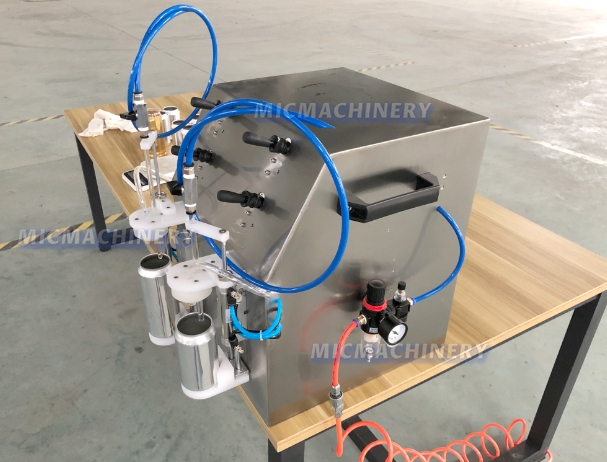

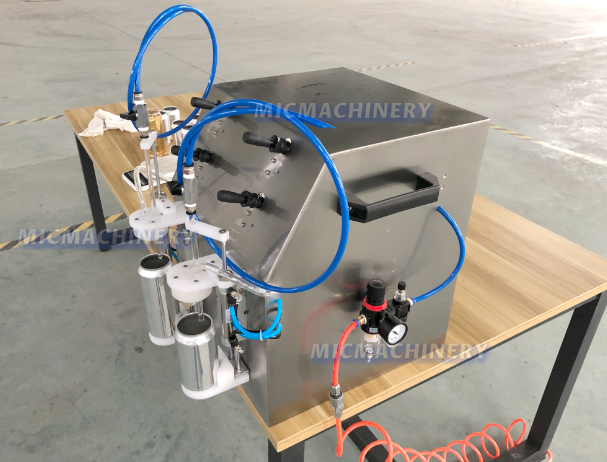

MIC Manual Carbonated Beverage Fill Equipment (8 cans per minute)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of high-quality industrial machinery specializing in beverage filling and packaging solutions. With extensive experience and expertise, we provide state-of-the-art equipment to meet the needs of the beverage industry. Our innovative solutions include a range of filling machines designed for both large-scale production and smaller operations. Our carbonated beverage fill equipment is engineered to deliver precision, reliability, and efficiency, ensuring that every product is filled to perfection while maintaining the integrity of the carbonation. At Jiangsu Mic Machinery, we are committed to providing cutting-edge technology that helps our customers achieve operational excellence.

|

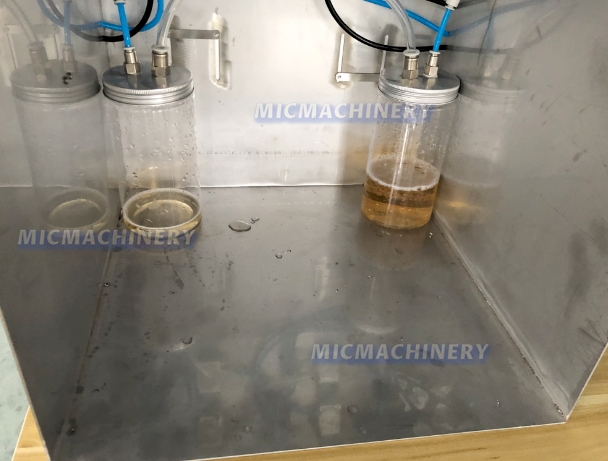

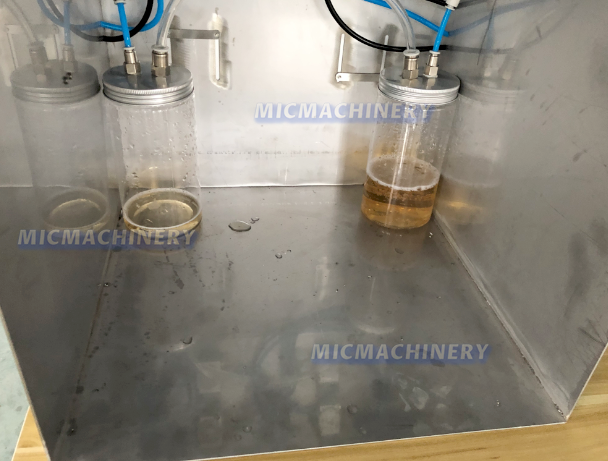

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Working Principle of Carbonated Filling Machine

The carbonated filling machine is designed to fill bottles with carbonated beverages while maintaining their fizz and carbonation levels. The system works on the principle of isobaric filling, where the beverage is dispensed into the bottle at the same pressure as the carbonation in the liquid, preventing the loss of CO2. The carbonated drink fill system ensures that carbonation remains intact, even during the filling process, allowing for precise and efficient operation. As the bottles are filled, the machine maintains constant pressure, ensuring that the liquid is dispensed evenly without excessive foam. After filling, the bottles are sealed, preserving the freshness and quality of the product.

Function of the Carbonated Filling Machine

The carbonated beverage fill equipment is designed to offer flexibility and efficiency for various filling applications. It is suitable for filling a wide range of carbonated beverages, such as sodas, sparkling water, energy drinks, and more. The carbonated filling machine is equipped with advanced technology that allows it to fill bottles accurately and at high speed, reducing waste and improving production efficiency. Its manual operation makes it ideal for smaller-scale production or for use in situations where automatic systems are not feasible. The machine also features easy-to-use controls, making it simple for operators to load and start the filling process.

Advantages of Carbonated Filling Machine

The carbonated filling machine offers numerous benefits for beverage producers:

1、Precision and Consistency

The carbonated beverage fill equipment ensures accurate filling levels and precise carbonation retention, improving product quality and consistency across production batches.

2、Cost-Effective

The manual design of the machine makes it a cost-effective solution for smaller-scale operations without sacrificing quality.

3、User-Friendly

With its simple manual operation, the machine is easy to set up and use, requiring minimal training for operators.

4、Durable Construction

Built with durable, high-quality materials, the carbonated drink fill system is designed to withstand heavy-duty use while maintaining high hygiene standards.

5、Versatile Application

The machine can handle a variety of bottle types and sizes, making it ideal for different beverage products and production line configurations.

6、Compact Design

Its compact and space-saving design makes it perfect for operations with limited space, while still providing full functionality.

7、Maintains Carbonation

The carbonated filling machine maintains the integrity of carbonation, ensuring the final product retains its freshness and taste.

This carbonated beverage fill equipment is an excellent choice for small to medium-scale beverage production, providing reliable, cost-effective solutions for high-quality carbonated drinks.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |