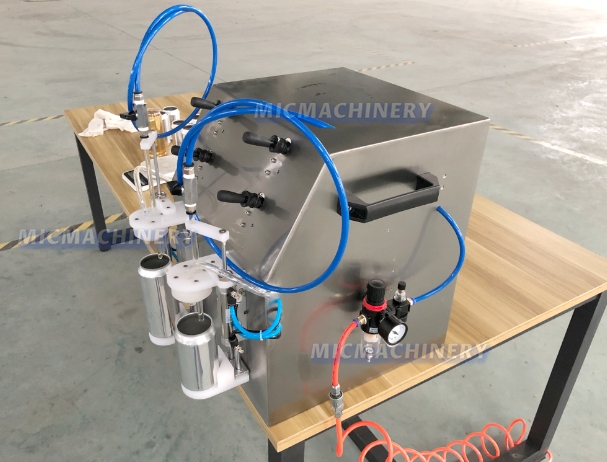

MIC Manual Beer Filling Machine (8 cans per minute)

MIC Manual Beer Filling Machine (8 Cans Per Minute): Reliable, Simple, and Efficient

Jiangsu Mic Machinery is proud to offer innovative and reliable beer filling equipment designed to meet the needs of small-scale breweries and craft beer producers. Our commitment to quality, precision, and efficiency is reflected in every product we design, including the MIC Manual beer filling machine, which offers a practical solution for breweries requiring moderate filling capacities. This machine is perfect for breweries that value simplicity, efficiency, and affordability in their beer packaging equipment.

|

|

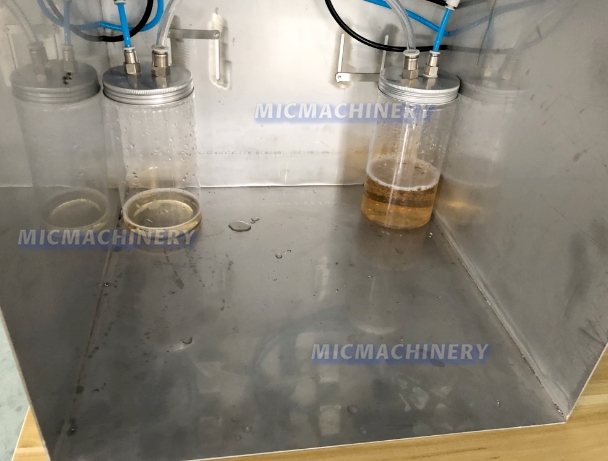

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can. |

|

Control Button |

|

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Features of MIC Manual Beer Filling Machine (8 Cans Per Minute)

The MIC Manual beer filling machine is designed to provide an efficient and reliable filling process for small-scale operations. With a filling capacity of 8 cans per minute, this machine is ideal for smaller breweries, startup craft breweries, and those needing a compact solution for their production lines.

1、Manual Operation with High Precision

This beer filling machine is manually operated, which gives operators more control over the filling process. Despite its manual nature, the machine offers high precision in filling, ensuring each can is filled to the right level, minimizing foam formation, and preserving the beer's quality and carbonation.

2、Compact and Space-Efficient Design

The MIC Manual beer packaging equipment is designed with small breweries in mind. Its compact size allows it to fit easily into limited space without sacrificing performance, making it a great option for breweries with smaller production areas or limited floor space.

3、Easy to Operate and Maintain

The machine’s manual operation means fewer complex components, reducing the chances of mechanical issues. Its straightforward design allows for easy operation and quick learning for new operators. Additionally, routine maintenance and cleaning are simple, keeping your brewery running smoothly without unnecessary downtime.

4、Durable Construction for Long-Term Use

Built with durable materials such as high-quality stainless steel, this beer filling equipment is designed for long-term use in demanding brewery environments. Its robust design ensures that it can handle the day-to-day demands of small-batch beer production while remaining reliable over time.

5、Flexibility in Container Size

While designed primarily for cans, the MIC Manual beer filling machine is also adaptable to different container types, including bottles, providing flexibility for breweries that need to switch between packaging formats quickly.

6、Low Cost and High Efficiency

With its manual operation and efficient design, this beer packaging equipment provides a cost-effective solution for small-scale breweries. The machine helps maintain high production quality at a low operational cost, making it ideal for startups or breweries with limited budgets.

7、Versatile for Various Beer Styles

The MIC Manual beer filling machine is suitable for filling a wide range of beer types, from lagers to ales and craft beers, ensuring the unique flavors and carbonation are preserved during the filling process.

Conclusion

The MIC Manual beer filling machine (8 cans per minute) is a high-quality, reliable solution for small-scale breweries seeking an affordable and efficient beer filling machine. Offering precise, manual filling with flexible operation, this beer packaging equipment provides excellent value while maintaining the quality of your beer. With its durable design, user-friendly operation, and cost-effective performance, the MIC Manual beer filling equipment is an excellent choice for small and craft breweries aiming for efficiency and quality in their production lines. At Jiangsu Mic Machinery, we are committed to providing the best beer filling equipment to help your brewery succeed and grow.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand | ||

| Buttons | Schneider (France) | ||

| Touch screen | Siemens (Optional) | ||

| AC Contactor | Schneider (France) | ||

| PLC | Mitsubishi (Japan) / Siemens (Optional) | ||

| Frequency changer | Schneider (France) | ||

| Air cylinder | AirTAC (China) / FESTO (Optional) | ||

| Solenoid valve | AirTAC (China) / FESTO (Optional) | ||

| Relay | Omron (Japan) / Schneider (France) | ||

| photoelectric sensor | Autonics (Korea) / Omron (Optional) | ||

| Proximity switch | Autonics / Omron (Optional) |