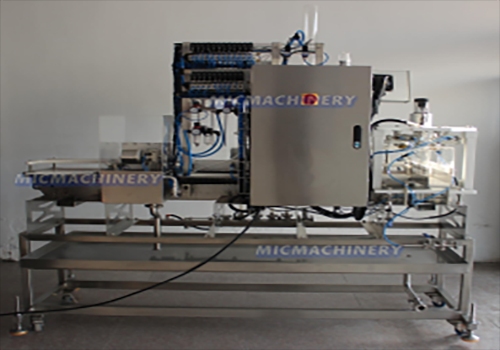

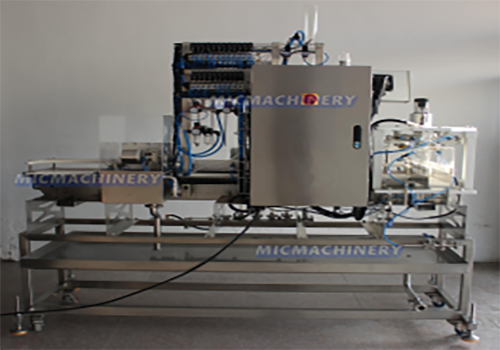

MIC Linear Soft Drink Packing Machine (1000-1500CPH)

Company Introduction

Jiangsu Mic Machinery is a globally recognized manufacturer of high-quality beverage packaging equipment. With years of expertise in the industry, we specialize in providing advanced machinery that meets the diverse needs of beverage producers worldwide. Our commitment to innovation and precision has earned us a reputation as a trusted partner for businesses looking to optimize their production processes. The MIC Linear soft drink packing machine is one of our premium products, designed to deliver exceptional performance and reliability in beverage production lines.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Working Principle of Soft Drink Filling Machine

The MIC Linear soft drink filling machine operates based on linear filling technology, ensuring precise and efficient filling of carbonated beverages. The process begins with bottles being fed into the machine through a conveyor system. Each bottle is securely positioned under the filling nozzles, where an advanced isobaric filling mechanism ensures accurate volume dispensing while maintaining the carbonation levels of the beverage.

For semi-automatic operations, the machine integrates manual oversight with automated functionalities, allowing manufacturers to maintain control over critical processes. This makes it an excellent choice for businesses transitioning to automation or those with moderate production requirements. Additionally, the integrated capping system seals each bottle tightly to prevent leakage and maintain product freshness. The entire process is designed to minimize waste, enhance efficiency, and ensure the integrity of the beverage.

Advantages of Soft Drink Filling Machine

1、Precision and Versatility

The MIC Linear soft drink packing machine delivers accurate filling for various bottle sizes and shapes, offering flexibility to manufacturers with diverse product lines.

2、Semi-Automatic Functionality

As a semi-automatic soft drink filling machine, it combines automation with manual control, providing businesses with a cost-effective solution for maintaining high-quality standards without fully transitioning to complete automation.

3、Enhanced Efficiency

The streamlined design of the machine reduces downtime and maximizes throughput, enabling manufacturers to meet production demands effectively.

4、Hygienic Design

Made from high-grade stainless steel, the machine complies with international hygiene standards, ensuring the safety and quality of the beverages.

5、User-Friendly Operation

The PLC control system, complete with a touch-screen interface, makes it easy to monitor and adjust machine settings for optimal performance.

6、Compact and Space-Saving

Its linear design minimizes space requirements, making it suitable for production lines with limited space availability.

7、Cost-Effectiveness

Combining precision and efficiency, this soft drink filling machine is a budget-friendly choice for small to medium-sized beverage manufacturers.

8、Low Maintenance Requirements

The robust construction and intelligent design ensure durability and ease of maintenance, reducing operational costs over time.

The MIC Linear soft drink packing machine embodies Jiangsu Mic Machinery's commitment to providing innovative, reliable, and efficient solutions for beverage manufacturers. Whether you are looking for a semi-automatic soft drink filling machine or a high-precision packaging solution, this machine is designed to meet your specific needs. Contact us today to learn more about how the MIC Linear soft drink filling machine can enhance your production line.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |