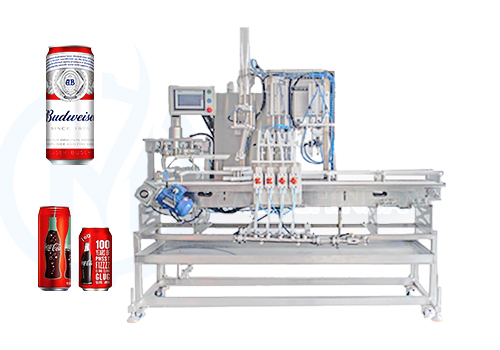

MIC Linear Carbonated Filling Machine (1000-1500CPH)

Machine is Suitable For

The MIC Linear carbonated filling machine is designed to meet the high standards of various industries producing carbonated beverages. It is ideal for small to medium-scale production facilities looking for an efficient and compact solution. Whether you are producing soda, sparkling water, or other carbonated drinks, this small carbonated drink filling machine ensures accurate and consistent results. It is suitable for businesses with diverse production needs, offering reliable performance for a wide range of bottle sizes and packaging materials such as PET and glass bottles.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Machine Features

The MIC Linear carbonated beverage fill equipment offers several standout features:

Efficient Linear Design: The linear configuration allows for smooth operation, enhancing production efficiency and reducing the footprint of the machine.

Isobaric Filling Technology: This ensures precise carbonation levels and prevents the loss of carbon dioxide during the filling process, maintaining the integrity of the beverage.

Multifunctional Capability: The machine integrates rinsing, filling, and capping in a seamless operation, reducing the need for additional equipment and saving valuable space.

User-Friendly Control System: Equipped with a touch-screen PLC control, operators can easily monitor and adjust the machine’s settings in real time.

Flexible Bottle Compatibility: The small carbonated drink filling machine can handle various bottle sizes, making it ideal for smaller production runs as well as larger volumes.

Hygienic Construction: Made from high-quality stainless steel, the machine is built to meet sanitation standards and ensure long-term durability.

Energy-Efficient Performance: The machine’s design focuses on reducing power consumption, making it both cost-effective and environmentally friendly.

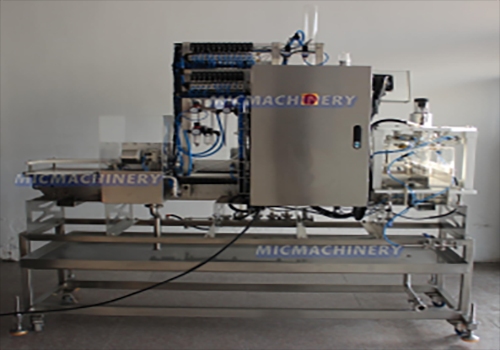

Machine Introduction

Jiangsu Mic Machinery’s MIC Linear carbonated filling machine is a highly efficient solution for businesses producing carbonated beverages. Designed with flexibility in mind, this carbonated beverage fill equipment provides consistent and accurate filling, maintaining the carbonation levels and ensuring every bottle meets the highest quality standards. Its compact linear configuration makes it an excellent choice for smaller production lines that still require high performance and reliability.

The machine’s robust features, including isobaric filling, automated control systems, and easy-to-maintain design, make it an ideal option for companies looking to expand or streamline their carbonated beverage production capabilities. The MIC Linear carbonated filling machine delivers precision, speed, and operational simplicity, helping manufacturers reduce downtime and increase production efficiency.

|

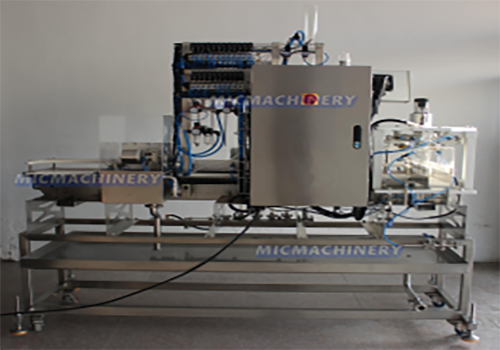

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |