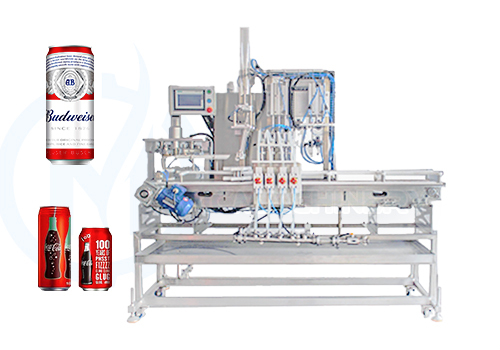

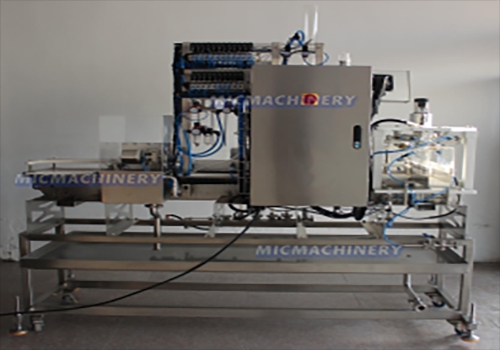

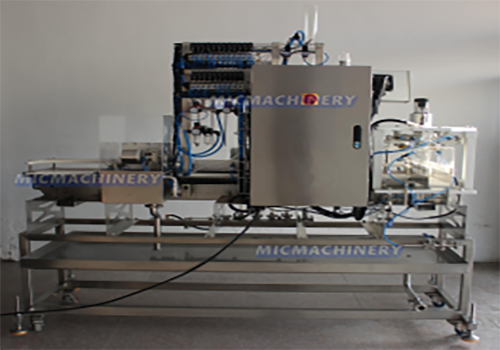

MIC Linear Can Filling Equipment (1000-1500CPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of advanced filling and packaging solutions for the beverage industry. With extensive experience in the production of high-quality can filling equipment, we are committed to delivering cutting-edge technology designed to meet the demands of modern production lines. Our products, such as the aluminum can filling machine and can filling and seaming machine, are recognized for their efficiency, reliability, and innovation. At Jiangsu Mic Machinery, we strive to help beverage manufacturers enhance productivity and product quality while maintaining a competitive edge in the market.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Features of Can Filling Machine

The MIC Linear can filling equipment is engineered to provide a seamless and efficient filling process for aluminum cans. With a capacity range of 1000 to 1500 cans per hour, it is an ideal choice for medium-scale production lines. This versatile aluminum can filling machine is designed to handle a variety of beverages, from carbonated soft drinks to non-carbonated liquids, while maintaining the integrity and quality of the product.

Equipped with state-of-the-art filling technology, the can filling equipment features precision filling valves that ensure accurate liquid levels in each can, minimizing overfills and product waste. The machine operates with an advanced control system that enables easy monitoring and adjustment of filling parameters such as speed, pressure, and filling volume. Its robust design also reduces the risk of contamination, ensuring that the beverage remains fresh and safe for consumers.

The can filling and seaming machine component of the system adds further automation, handling the critical tasks of sealing and closing the cans after filling. This seamless integration of filling and seaming ensures that each can is tightly sealed, maintaining carbonation levels and preventing leakage, which is essential for carbonated beverages. This automation greatly enhances operational efficiency, making it an ideal solution for businesses looking to streamline their production process.

Advantages of Can Filling Machine

1、High Efficiency and Consistent Output

With a filling capacity of 1000 to 1500 cans per hour, the MIC Linear can filling equipment delivers consistent and high-quality production. Its linear design allows for better space utilization while ensuring that production output meets the demands of medium-volume manufacturers.

2、Precision and Accuracy

The aluminum can filling machine utilizes advanced filling technology to ensure precise filling, reducing waste and maintaining product quality. Each can is filled with the exact volume of liquid, ensuring consistency across all cans.

3、Fully Automated Process

The integration of the can filling and seaming machine automates both the filling and sealing processes, reducing the need for manual intervention and minimizing human error. This results in a more efficient production line and faster turnaround times.

4、Versatility

The can filling equipment is highly adaptable, capable of filling both carbonated and non-carbonated beverages. Whether you’re filling sodas, juices, or teas, this equipment can handle a wide range of liquids with ease, offering flexibility to your production line.

5、Compact Design

The linear layout of the system minimizes its footprint, making it an excellent choice for smaller production areas where space is limited. Despite its compact size, the machine offers high-speed performance without sacrificing filling accuracy or operational efficiency.

6、Improved Sealing Quality

The can filling and seaming machine component ensures that cans are tightly sealed, maintaining freshness and preventing leaks. This is crucial for preserving the quality of carbonated drinks and preventing contamination or spoilage.

7、User-Friendly Operation

The machine is equipped with an easy-to-use interface that allows operators to monitor and control the filling process effortlessly. The control system can be adjusted to fit different production needs, allowing for smooth operations and minimal downtime.

8、Durability and Reliability

Built from high-quality materials, the aluminum can filling machine is designed for long-term durability. It operates continuously with minimal maintenance, offering a reliable solution for production lines that demand uptime and longevity.

9、Energy-Efficient

The machine is designed with energy-saving features, ensuring that operational costs are kept to a minimum without sacrificing performance. This makes it a cost-effective solution for businesses looking to optimize their production process.

10、Enhanced Hygiene Standards

The design of the can filling equipment minimizes the chances of contamination during the filling and sealing process. This high level of hygiene is particularly important in the beverage industry, where product safety is a top priority.

In conclusion, the MIC Linear can filling equipment offers beverage manufacturers a reliable, efficient, and versatile solution for their production lines. By combining precise filling capabilities, automation, and cost-saving features, this can filling and seaming machine sets a new standard for medium-scale filling operations. Whether you’re filling soda, juices, or other beverages, this system will help streamline your production while ensuring product quality and safety.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |