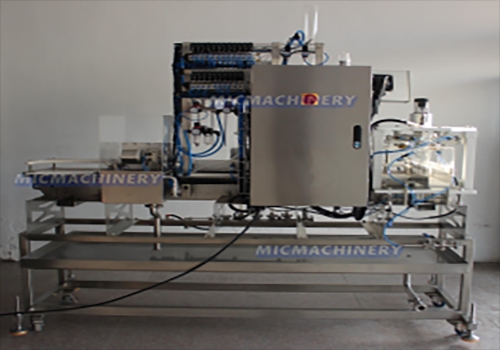

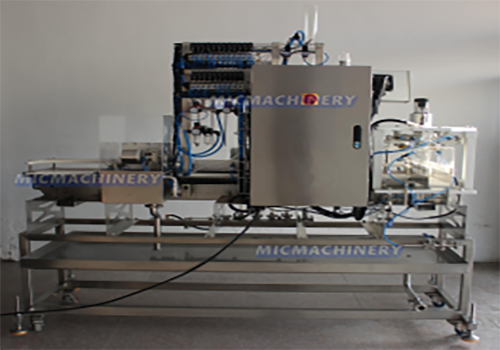

MIC Beer Filling Equipment (1000-1500CPH)

MIC Beer Filling Equipment (1000-1500CPH): Precision and Efficiency for Mid-Scale Breweries

Jiangsu Mic Machinery is a leading manufacturer of advanced beer filling equipment designed to meet the growing demands of the modern brewing industry. With a commitment to quality, innovation, and efficiency, we provide state-of-the-art solutions that help breweries of all sizes streamline their production processes. Our beer packaging equipment is engineered to provide high-performance, reliability, and precision, ensuring that every batch of beer is filled with the utmost care and accuracy. The MIC beer filling equipment (1000-1500CPH) is one of our flagship products, designed to offer exceptional value for breweries with moderate production volumes.

|

|

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Advantages of MIC Beer Filling Equipment (1000-1500CPH)

The MIC beer filling equipment offers several key advantages that make it an ideal choice for mid-sized breweries.

1、Cost-Effective for Mid-Scale Breweries

Offering a filling capacity of 1000-1500 cans or bottles per hour, this beer packaging equipment provides an affordable option for breweries with moderate production needs. It strikes the perfect balance between cost and performance, allowing you to scale your production without overinvesting in larger systems.

2、Increased Efficiency

With automated controls and precision filling technology, the MIC beer filling equipment reduces the time and labor needed for each batch. This boosts production efficiency, reduces human error, and ensures consistent filling with every container.

3、Flexible for Different Beer Types

Whether you're producing standard beer or specialty craft beer, this equipment is designed to handle a wide range of beer styles. The precise filling technology ensures that the delicate flavors and carbonation of craft beer are preserved during the filling process.

4、High-Quality Output

The advanced filling system minimizes foam formation and overfilling, ensuring that the beer maintains its freshness and quality. The consistent performance of this craft beer filling machine helps maintain a high-quality product that meets the expectations of consumers.

5、Long-Term Reliability

Built with durable materials and designed for continuous operation, the MIC beer filling equipment is a reliable long-term investment. It minimizes downtime and maintenance costs, allowing breweries to focus on production and growth.

Conclusion

The MIC beer filling equipment (1000-1500CPH) offers a high-quality, efficient, and cost-effective solution for mid-sized breweries. Designed for precise filling, high capacity, and versatility, this beer packaging equipment is perfect for breweries looking to optimize their production processes while maintaining the quality and consistency of their beer. With advanced technology, durable construction, and energy efficiency, the MIC craft beer filling machine is an essential tool for breweries that want to scale production while preserving the premium quality of their products. At Jiangsu Mic Machinery, we are committed to providing the best beer filling equipment to help breweries succeed and grow in a competitive market.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |