MIC-360D Beer Can Labeling Machine (Speed 600BPM)

Introduction to Our Cans Labeling Machine

Jiangsu Mic Machinery specializes in providing advanced labeling solutions to meet the demands of high-volume production lines. Our cans labeling machine is designed to efficiently apply labels to various types of cans, ensuring precise and professional labeling for industries such as food, beverage, and chemicals. Whether you need a system for small-scale production or large-scale manufacturing, this machine guarantees accuracy, speed, and consistency.

With its inline can labeler capabilities, this machine seamlessly integrates into existing production lines, optimizing workflow and minimizing downtime. Additionally, our high speed can labeler ensures that labeling is completed rapidly without compromising on quality, making it the perfect solution for businesses that require efficiency and reliability.

Description of the Cans Labeling Machine

The cans labeling machine is built for high-performance labeling, capable of applying labels to aluminum, tin, and plastic cans with exceptional precision. Equipped with advanced automation, this machine ensures that labels are applied seamlessly, reducing waste and improving overall product presentation.

As an inline can labeler, this system is designed for smooth, continuous operation. It allows for effortless integration into production lines, eliminating bottlenecks and ensuring uninterrupted labeling processes. The machine’s adaptable settings enable it to handle different can sizes, label formats, and application techniques, providing unmatched versatility.

Our high speed can labeler is engineered for rapid labeling without sacrificing accuracy. With high-speed capabilities, it can handle large-scale production demands while maintaining precision and consistency. The user-friendly control panel makes it easy to adjust settings for different label placements, allowing quick transitions between production runs.

Key Features:

- High-speed performance for large-scale production environments.

- Inline can labeler integration for smooth and efficient workflow.

- Advanced sensor technology to ensure precise label placement.

- Versatile design to accommodate various can sizes and label types.

- User-friendly controls for easy operation and quick adjustments.

Conclusion

Jiangsu Mic Machinery’s cans labeling machine provides a high-efficiency, high-precision solution for businesses looking to optimize their labeling process. Whether you require an inline can labeler for seamless integration or a high speed can labeler for large-scale production, our equipment ensures reliable performance and superior labeling quality. Let us help you enhance your production line with cutting-edge labeling technology.

|

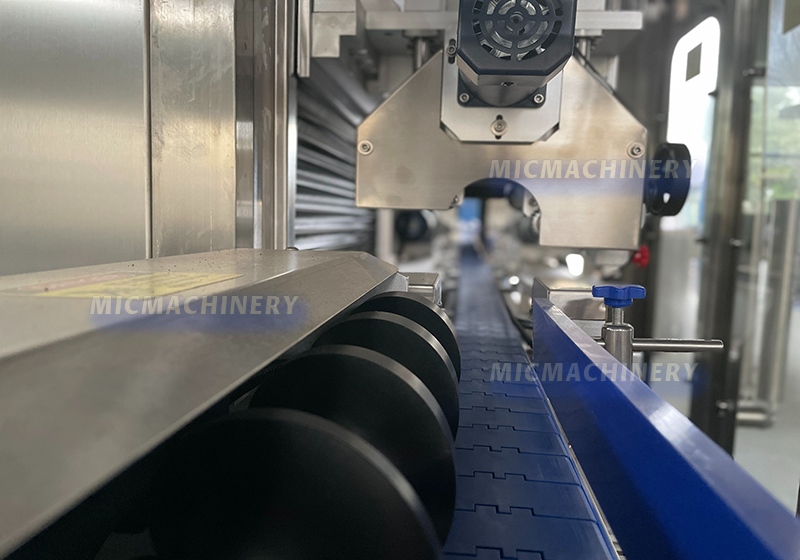

Bottle feeding device

The bottle feeding device in a shrink sleeve labeling machine is designed to ensure smooth, continuous, and precisely timed delivery of bottles into the labeling zone. It typically includes a conveyor system and spacing mechanism that arranges bottles at equal intervals, allowing accurate sleeve placement without collision or misalignment. This system ensures seamless coordination with the sleeving and cutting units, enhancing labeling accuracy and production efficiency. The bottle feeding device supports various bottle shapes and sizes, making it ideal for high-speed, automated packaging lines. |

|

Auto sleeving device

The auto sleeving device is the core mechanism of a shrink sleeve labeling machine, responsible for automatically applying shrink sleeves onto containers with high speed and precision. It operates by synchronizing the film feed, cutting, and application in one continuous motion. After the film is cut into individual sleeves, the auto sleeving device opens and positions each sleeve precisely over the passing bottle or container using servo-driven mandrels or drop tubes. This fully automated system ensures consistent sleeve placement, minimizes material waste, and adapts to various container shapes—making it essential for modern, high-efficiency packaging lines. |

|

|

Send label wheel

The send label wheel in a shrink sleeve labeling machine is a precision-driven component that controls the stable feeding of shrink film from the roll to the cutting unit. Working in coordination with the pulling wheels and servo system, the send label wheel ensures smooth and accurate label delivery without tension loss or film misalignment. It plays a crucial role in maintaining labeling consistency, especially at high production speeds, and supports a wide range of film materials and thicknesses for various bottle shapes and sizes. |

Automatic Sleeve Labeling Machine Key Features And Benefits:

1.Speed and Efficiency: Automatic sleeve labeling machines are designed to handle high-speed production lines and can label up to thousands of containers per hour. The machine is equipped with advanced features like automatic feeding, orientation, and cutting, which ensures efficient and consistent labeling.

2.Accurate Labeling: An automatic sleeve labeling machine uses sensors and servo motors to ensure precise label placement and alignment, minimizing the risk of label errors. The machine can also detect and reject containers with incorrect or missing labels, ensuring accurate labeling for each container

3.Versatile Labeling Options: An automatic sleeve labeling machine can handle different types of labels, including full-body sleeves, tamper-evident seals, and promotional sleeves. This versatility allows for greater flexibility in labeling options and enables companies to customize their labels according to their branding needs.

4.Cost Savings: The automation of the labeling process with an automatic sleeve labeling machine can significantly reduce labor costs and minimize material waste due to consistent and accurate labeling. This can lead to significant cost savings for the company.

5.Increased Production Capacity: The high-speed and consistent labeling provided by an automatic sleeve labeling machine can increase production capacity, allowing companies to meet growing demand and expand their business.

6.Improved Branding and Marketing: The full-body sleeves or promotional sleeves provided by the automatic sleeve labeling machine can improve branding and marketing efforts by providing a visually appealing and eye-catching label that attracts customers.

In summary, an automatic sleeve labeling machine offers many benefits, including high-speed and efficient labeling, accurate and consistent label placement, versatility in labeling options, cost savings, increased production capacity, and improved branding and marketing efforts.

| Input Power | 8.0kw |

| Input Voltage | 3,380 1220VAC |

| Production Efficiency | 600 bottle/min |

| Size Of Host Machine | L2800mm*W1200mm*H2200mm |

| Applicable Diameter Of Bottle Body | 48-96mm |

| Applicable Length Of Label | 30-250mm |

| Applicable Thickness Of Label | 0.03-0.13mm |

| Applicable Intemal Diameter Of Paper Tube | 5"- -10" free adjustment |