MIC 24-24-8 Mineral Water Packing Machine

MIC 24-24-8 Mineral Water Packing Machine

Company Introduction

Mic Machinery is a trusted manufacturer of beverage packaging solutions, committed to delivering high-performance, precision-engineered equipment for global clients. With advanced R&D and a dedicated engineering team, we provide innovative systems tailored to meet the demands of modern beverage production. One of our flagship products is the MIC 24-24-8 Mineral Water Packing Machine, designed to ensure speed, hygiene, and efficiency in water bottling operations.

|

Control Panel The Control Panel with Water Filling Machine offers precise control over the filling process. With an intuitive interface, it ensures accurate volume measurement, efficient operation, and seamless automation for water bottling. |

|

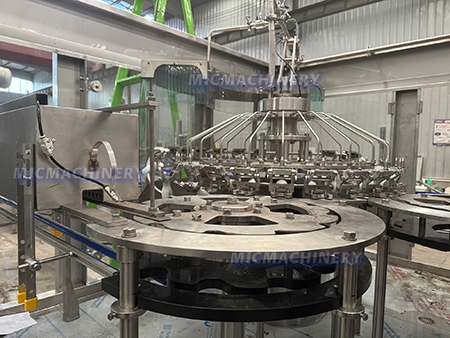

Filling Head The Filling Head with Water Filling Machine is designed to ensure precise and consistent filling of water bottles. Equipped with advanced technology, it minimizes spillage and ensures accurate volume measurement for each bottle. Ideal for high-speed, automated water bottling processes, it enhances efficiency and reduces downtime. |

|

Working Principle

The mineral water packing machine follows an integrated rotary system with three main functions—rinsing, filling, and capping:

1)Rinsing Station (24 heads): Empty bottles are automatically clamped and rinsed with sterile water to remove dust and impurities.

2)Filling Station (24 heads): Clean bottles are filled with mineral water using gravity or pressure filling methods, ensuring accuracy and hygiene.

3)Capping Station (8 heads): After filling, bottles move to the capping unit where caps are securely sealed to prevent leakage and contamination.

Features and Advantages

▪ High Production Efficiency: Handles up to 6000 bottles per hour with continuous operation.

▪ Sanitary Design: All contact parts are made from food-grade stainless steel for cleanliness and safety.

▪ Touchscreen Control Panel: Easy to operate with real-time monitoring and fault detection.

▪ Compact Integration: Combines rinsing, filling, and capping into one streamlined unit.

▪ Flexible Bottle Compatibility: Suitable for different bottle sizes, making it a versatile machine for mineral water packaging.

Applications

This mineral water machine is ideal for bottling purified water, spring water, and other non-carbonated beverages. It is widely used in water plants, beverage factories, and contract packaging facilities. Its modular design makes it easy to expand or adapt for growing production needs.

Conclusion

The MIC 24-24-8 Mineral Water Packing Machine offers a complete solution for efficient and hygienic water bottling. Whether you’re starting a new line or upgrading an existing one, this machine for mineral water delivers the reliability and performance your operation demands. Trust Mic Machinery to support your success in the bottled water industry.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |