MIC 18-18-6 Pet Bottle Filling Line (5000-8000BPH)

MIC 18-18-6 Pet Bottle Production Line

Company Overview

Jiangsu Mic Machinery is a leading manufacturer of advanced beverage production lines, specializing in pet bottle production lines, pet bottle filling lines, and other high-performance packaging machinery. With years of expertise in the industry, we are committed to delivering innovative and reliable solutions to beverage producers worldwide. Our focus on quality, efficiency, and customer satisfaction ensures that every machine we design is built to perform at the highest standards.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

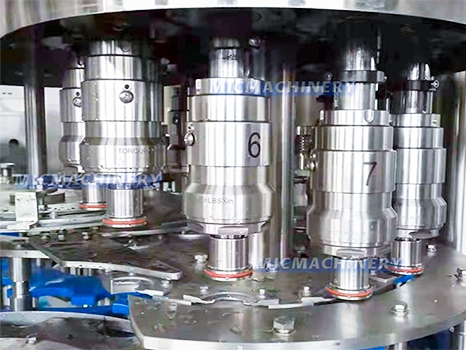

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Product Features

The MIC 18-18-6 Pet Bottle Production Line is a fully automated system engineered for high-speed filling and packaging of PET bottles. This robust production line integrates the latest technology to provide a seamless and efficient solution for beverage producers. It is designed to handle a wide range of bottle sizes and liquid types, including carbonated drinks, water, juices, and other beverages, making it incredibly versatile and adaptable to the needs of various production environments.

Key Features of the MIC 18-18-6 Pet Bottle Production Line

Advanced Filling Technology

The pet bottle filling line is equipped with precision filling valves that ensure accurate and efficient liquid dispensing. This reduces product wastage, maintains consistency, and guarantees high filling accuracy for every bottle.

Comprehensive Bottle Handling System

The system includes an automatic bottle unscrambler, air conveyor, and bottle rinser, all designed to improve efficiency and reduce manual intervention. The pet bottle production line ensures that each bottle is properly cleaned and sterilized before filling, maintaining hygiene standards.

Integrated Capping and Labeling

The MIC 18-18-6 Pet Bottle Production Line integrates automatic capping and labeling systems. The capping station securely seals each bottle, while the labeling system ensures that every bottle is properly labeled with product information and branding. This integrated process reduces bottlenecks and increases operational efficiency.

Energy-Efficient Design

Designed with energy conservation in mind, this production line uses state-of-the-art components that reduce electricity consumption. By optimizing energy use, the pet bottle filling line helps to lower operational costs, making it an economical choice for long-term production.

User-Friendly Interface

The pet bottling line is equipped with an easy-to-use control panel that allows operators to monitor and manage the system with ease. The intuitive interface makes it simple to adjust settings, troubleshoot, and ensure optimal performance.

Advantages

1.High Efficiency and Reliability

The MIC 18-18-6 Pet Bottle Production Line is designed for continuous operation, offering high efficiency and reliability. This helps ensure minimal downtime, reducing the need for frequent maintenance and ensuring consistent production.

2.Versatile Application

The line is suitable for a wide range of beverage types, including carbonated soft drinks, mineral water, juices, and teas. Its versatility makes it a valuable asset for manufacturers producing various products on the same line.

3.Precise and Consistent Filling

The system’s precision filling technology ensures that each bottle is filled accurately, preventing overfills or underfills. This not only improves product quality but also minimizes waste and optimizes material usage.

4.Low Maintenance

The pet bottle production line is built for durability and reliability, with easy maintenance procedures that minimize downtime. Routine checks and servicing are simple, reducing the burden on production teams and improving overall uptime.

5.Scalable and Flexible

As your production needs grow, this system can be easily scaled to accommodate higher output levels. It’s adaptable to changes in production volumes and product types, making it an ideal solution for businesses looking to expand their operations.

In conclusion, the MIC 18-18-6 Pet Bottle Production Line offers the perfect balance of speed, precision, and efficiency for large-scale beverage production. Designed with advanced features and a focus on energy conservation and ease of use, this line is the ideal solution for businesses looking to enhance their bottling processes and meet the growing demand in the beverage industry.

|

Model |

|||

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |