MIC 18-18-6 Cold Drink Bottle Packing Machine (8000-10000 BPH)

MIC 18-18-6 Cold Drink Bottle Packing Machine

Working Principle of the Drink Bottling Machine

The MIC 18-18-6 cold drink bottle packing machine operates as a highly efficient and automated solution for bottling and packing soft drinks at high speeds. The system seamlessly integrates with other parts of the production line, including the soft drink bottling machine, to offer an end-to-end solution for bottling, capping, and packing.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

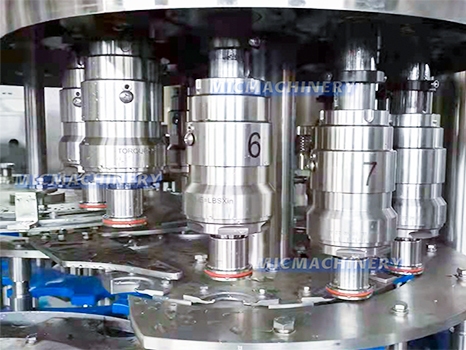

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Filling Process

The machine begins with the filling of bottles, which can be carbonated or non-carbonated drinks, using advanced volumetric or gravity-based filling methods. The drink bottling machine ensures precise and consistent filling levels, reducing waste and improving product quality.

Capping: After the filling process, the bottles move to the capping station where a tightly sealed cap is applied. This guarantees the freshness of the product and ensures that the beverage is securely contained.

Packing: Following the capping, the filled bottles are transferred to the packing section of the system, where they are grouped into cartons or shrink-wrapped. The cold drink bottle packing machine efficiently handles this step, organizing the bottles into packed units for shipment. The machine can automatically stack, seal, and prepare the drinks for storage or distribution.

The combination of these processes ensures high throughput, accuracy, and efficiency while maintaining product quality throughout the entire packaging process.

Advantages of the Drink Bottling Machine

1、High-Speed Operation

The MIC 18-18-6 cold drink bottle packing machine boasts a high-speed production capacity, handling up to 8000-10000 bottles per hour. This makes it ideal for medium to large-scale production lines, helping manufacturers meet high demand while maintaining product consistency.

2、Hygiene and Cleanliness

Hygiene is a critical aspect of beverage production, and this machine is designed to meet the highest standards of cleanliness. The soft drink bottling machine features a built-in rinsing system that ensures every bottle is thoroughly cleaned before filling, reducing the risk of contamination.

3、Energy-Efficiency

The MIC 18-18-6 drink bottling machine is engineered with energy-saving technology, reducing overall energy consumption while still maintaining high performance. This translates into lower operational costs and greater sustainability for businesses.

4、Versatility

This machine is highly versatile, capable of handling a wide range of beverages, including soft drinks, juices, flavored waters, and more. Its flexibility ensures that it can accommodate various beverage types, making it a great investment for businesses with diverse product lines.

5、Minimal Downtime

The MIC 18-18-6 cold drink bottle packing machine is built with high-quality materials that are durable and long-lasting. Its robust design minimizes the need for maintenance, reducing downtime and allowing for more continuous production.

6、Automated and Efficient

The system integrates advanced automation technology, reducing the need for manual labor and enhancing the overall efficiency of the production line. The smooth operation of the soft drink bottling machine ensures higher productivity levels, reducing labor costs while increasing output.

7、Cost-Effective

The machine offers excellent value for businesses, combining high performance, energy efficiency, and low maintenance requirements. It allows manufacturers to achieve a high level of productivity at a lower cost, enhancing the return on investment (ROI).

8、User-Friendly Interface

The drink bottling machine is designed with an easy-to-use control panel, making it simple for operators to monitor and adjust settings during production. This user-friendly interface reduces errors and improves the overall operation of the machine.

Conclusion

The MIC 18-18-6 cold drink bottle packing machine is a high-performance, reliable, and efficient solution for soft drink production lines. With its impressive speed, versatile operation, and cost-saving features, it is the ideal choice for businesses looking to enhance their bottling and packaging capabilities. Trust Jiangsu Mic Machinery to provide you with innovative solutions that increase efficiency and meet the growing demands of the beverage industry.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |