MIC 18-18-1 Carbonated Beverage Bottling Machine (Speed 800-1500BPH)

Company Introduction

Jiangsu Mic Machinery is a renowned leader in the beverage bottling industry, providing high-performance bottling solutions for a variety of beverage types. With a strong focus on innovation and quality, we specialize in the design and manufacturing of advanced carbonated beverage bottling machines and equipment. Our state-of-the-art machinery is built to improve efficiency, reduce operational costs, and ensure high-quality production standards. As a trusted partner to beverage manufacturers around the world, we strive to meet the growing demands of the industry by offering durable and reliable carbonated beverage bottling equipment tailored to various production needs.

|

|

Beer bottling production line A beer bottling production line is a fully automated system designed for rinsing, filling, capping, and labeling beer bottles efficiently, ensuring high productivity and consistent quality for breweries. |

|

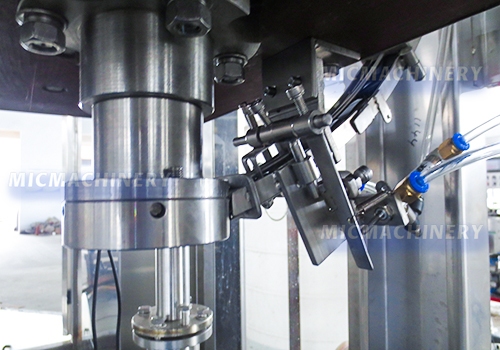

Capping Part The capping part of the beer bottling machine securely places and tightens caps on bottles after filling. It ensures reliable sealing with adjustable torque settings, preventing leaks and maintaining product integrity. |

|

|

|

Filling part The filling part of the beer bottle filler ensures precise, efficient filling with minimal wastage. It utilizes gravity or pressure filling methods to achieve accurate fill levels, accommodating various bottle types. |

Features of Beverage Bottling Machine

The beverage bottling machine is engineered with advanced technology to handle the complexities of carbonated beverage production. This machine is equipped with several key features that ensure precision, speed, and versatility.

Precise Carbonation Control:One of the standout features of this carbonated beverage bottling machine is its ability to maintain optimal carbonation levels throughout the bottling process. Specialized systems ensure that the beverage maintains the perfect level of carbonation, avoiding over-carbonation or flat drinks. This is crucial for maintaining the flavor and texture of carbonated beverages, including sodas, sparkling waters, and energy drinks.

Multi-Stage Filtration and Cleaning System:Hygiene is a priority in beverage production, and the carbonated beverage bottling equipment includes a multi-stage filtration and cleaning system. This ensures that all bottles are thoroughly cleaned before filling and prevents contamination, guaranteeing that the final product is safe for consumption. The machine’s cleaning features adhere to global industry standards, ensuring that all sanitation protocols are followed.

High-Speed Filling and Sealing:The beverage bottling machine features an automatic high-speed filling and sealing system. With high-speed filling valves that can be adjusted for different bottle sizes, the machine efficiently fills bottles without spilling or wasting product. After filling, the machine seals each bottle with precision, maintaining freshness and preventing contamination.

Versatility in Bottle Size and Shape:This machine is capable of handling a wide range of bottle sizes and shapes, offering flexibility to beverage manufacturers. Whether it's a small 250ml bottle or a larger 2-liter container, the carbonated beverage bottling equipment can be adjusted quickly and easily to accommodate various packaging requirements.

Automated Labeling and Packaging Integration:The beverage bottling machine is fully integrated with automated labeling and packaging systems. After the bottles are filled and sealed, they are automatically labeled with product information, making the production process seamless from start to finish. The labeling system ensures that each bottle is clearly marked with accurate and professional labels, which helps maintain brand consistency.

Advantages of Beverage Bottling Machine

1、High Efficiency and Throughput

The carbonated beverage bottling machine is designed for high-speed, high-efficiency operations. With its capacity for rapid filling and sealing, it significantly boosts production throughput, allowing manufacturers to meet the demands of high-volume production while maintaining quality and consistency. This efficiency minimizes downtime and maximizes output, increasing overall productivity.

2、Cost-Effectiveness

The carbonated beverage bottling equipment offers excellent value for its capabilities. By automating multiple stages of the bottling process, it reduces labor costs and minimizes human error, resulting in savings for the manufacturer. The long-term savings gained from increased operational efficiency make this machine a wise investment for any beverage manufacturer.

3、Durability and Reliability

Built from high-quality materials, the carbonated beverage bottling equipment is designed to withstand continuous operation in high-demand environments. Its robust construction ensures long-lasting durability, reducing the need for frequent repairs and increasing the operational lifespan of the equipment. This reliability is essential for beverage manufacturers who require consistent performance in their production lines.

4、Scalability

The beverage bottling machine is scalable, which means it can be used for both small-scale operations and large-scale production. As your business grows, the system can be easily adjusted to handle higher volumes, making it an ideal solution for expanding production lines. Its scalability ensures that it remains a valuable asset as your needs evolve.

5、Environmental Sustainability

The machine is designed with energy efficiency in mind, reducing its environmental impact by using less energy compared to older, less efficient systems. Additionally, its precise filling system minimizes product wastage, contributing to sustainable production practices.

In conclusion, the MIC 18-18-1 carbonated beverage bottling machine offers a comprehensive solution for beverage manufacturers seeking high-quality, efficient, and cost-effective equipment. With its advanced features, such as precise carbonation control, high-speed filling, and automated labeling, this machine meets the diverse needs of the modern beverage industry. The durability, scalability, and reliability of this carbonated beverage bottling equipment make it a smart investment that will drive growth and ensure the production of high-quality beverages for years to come.

|

Model No. |

12-12-1 |

18-18-1 |

18-18-6 |

24-24-6 |

32-32-8 |

|

Rinsing Heads |

12 |

18 |

18 |

24 |

32 |

|

Filling Heads |

12 |

18 |

18 |

24 |

32 |

|

Capping Heads |

1 |

1 |

6 |

6 |

8 |

|

Filling Speed |

500-1000BPH |

800-1500BPH |

2000-4000BPH |

4000-5000BPH |

4800-7500BPH |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |